Scroll Down

Scroll Down

Poly Pazhou Facade

Poly Pazhou Facade

Poly Pazhou Facade

Objects

Objects

2012 - 2016

2012 - 2016

2012 - 2016

Poly Pazhou Center

Poly Pazhou Center

Poly Pazhou Center

(ML/W) Scope

(ML/W) Scope

(ML/W) Scope

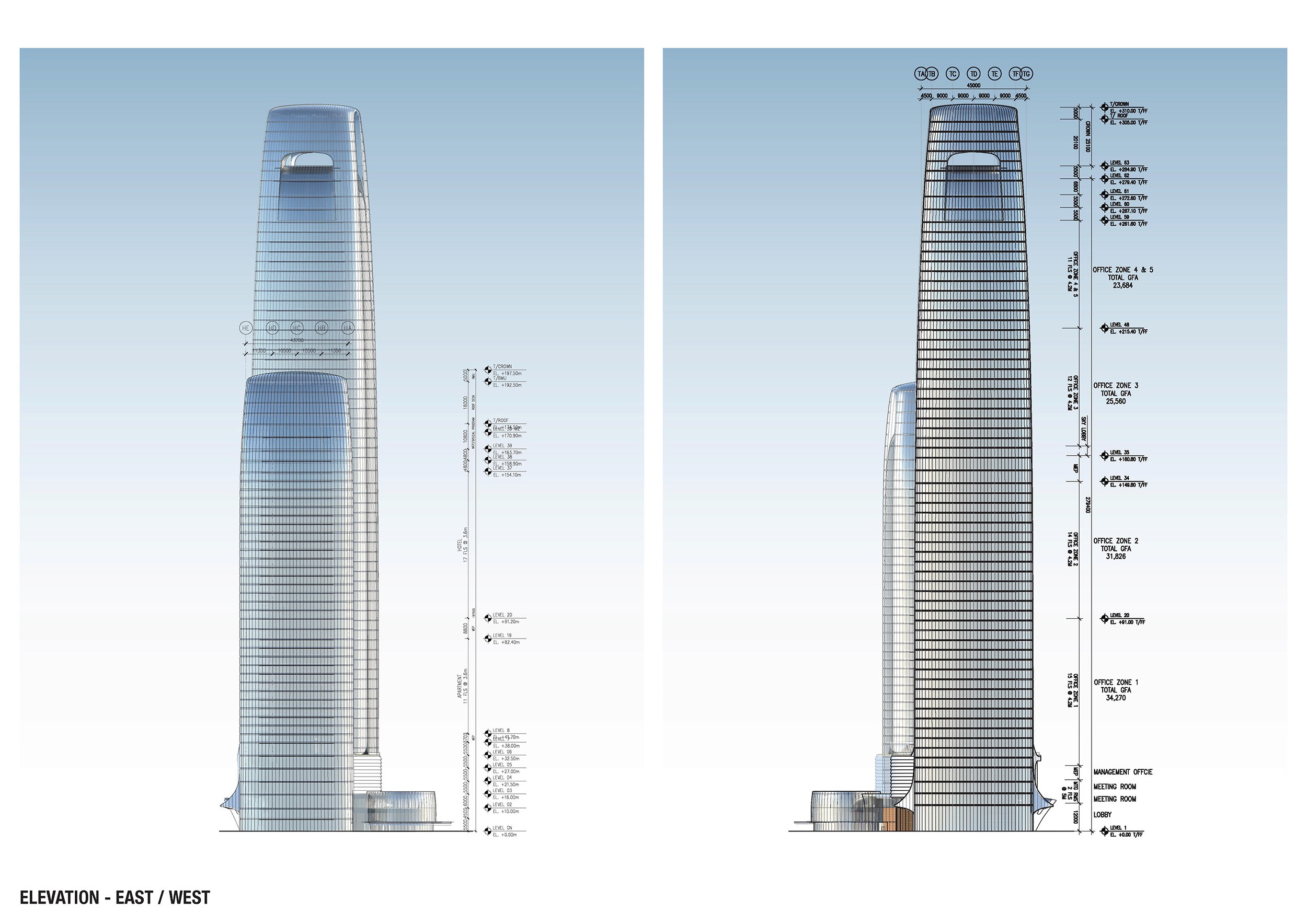

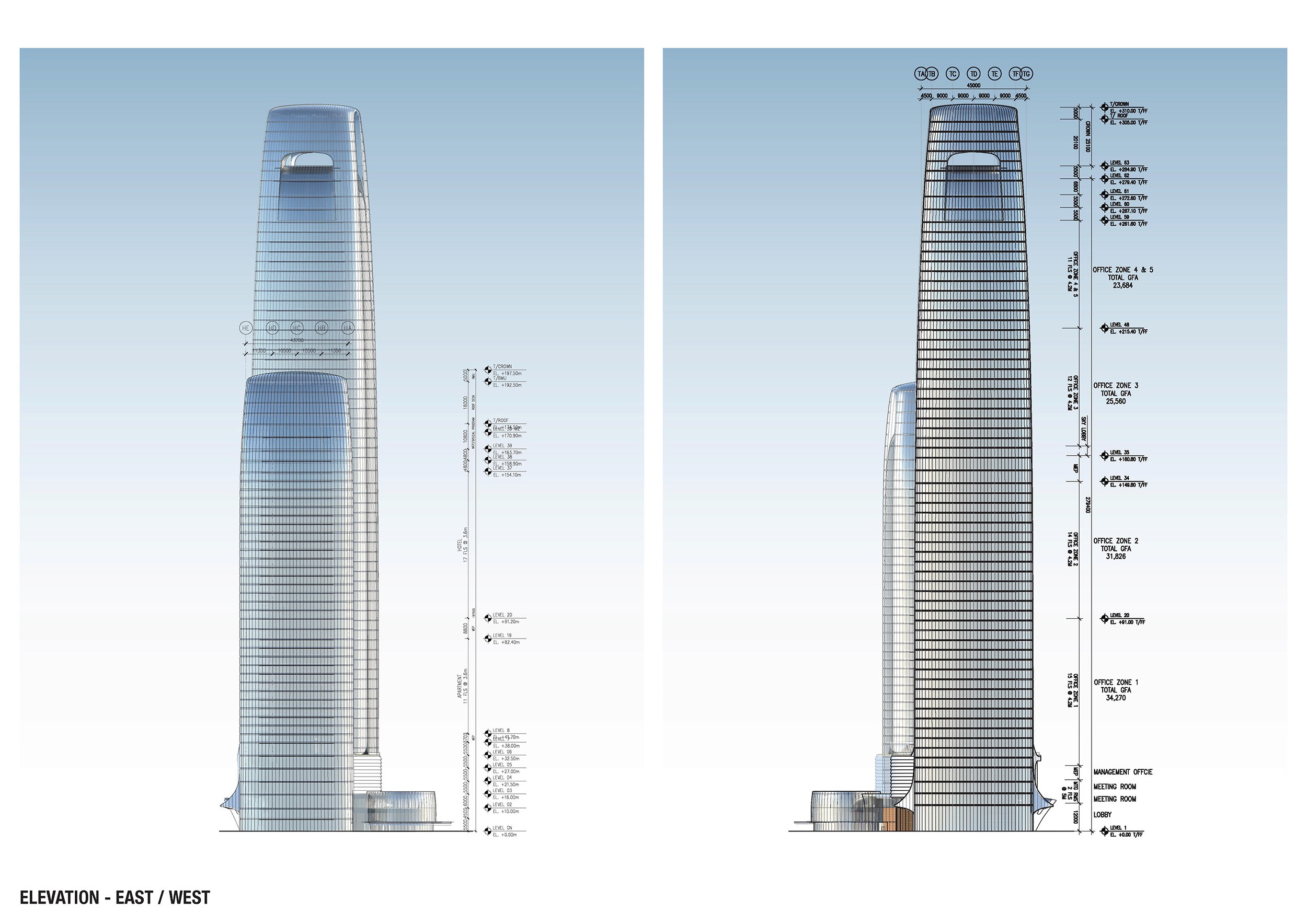

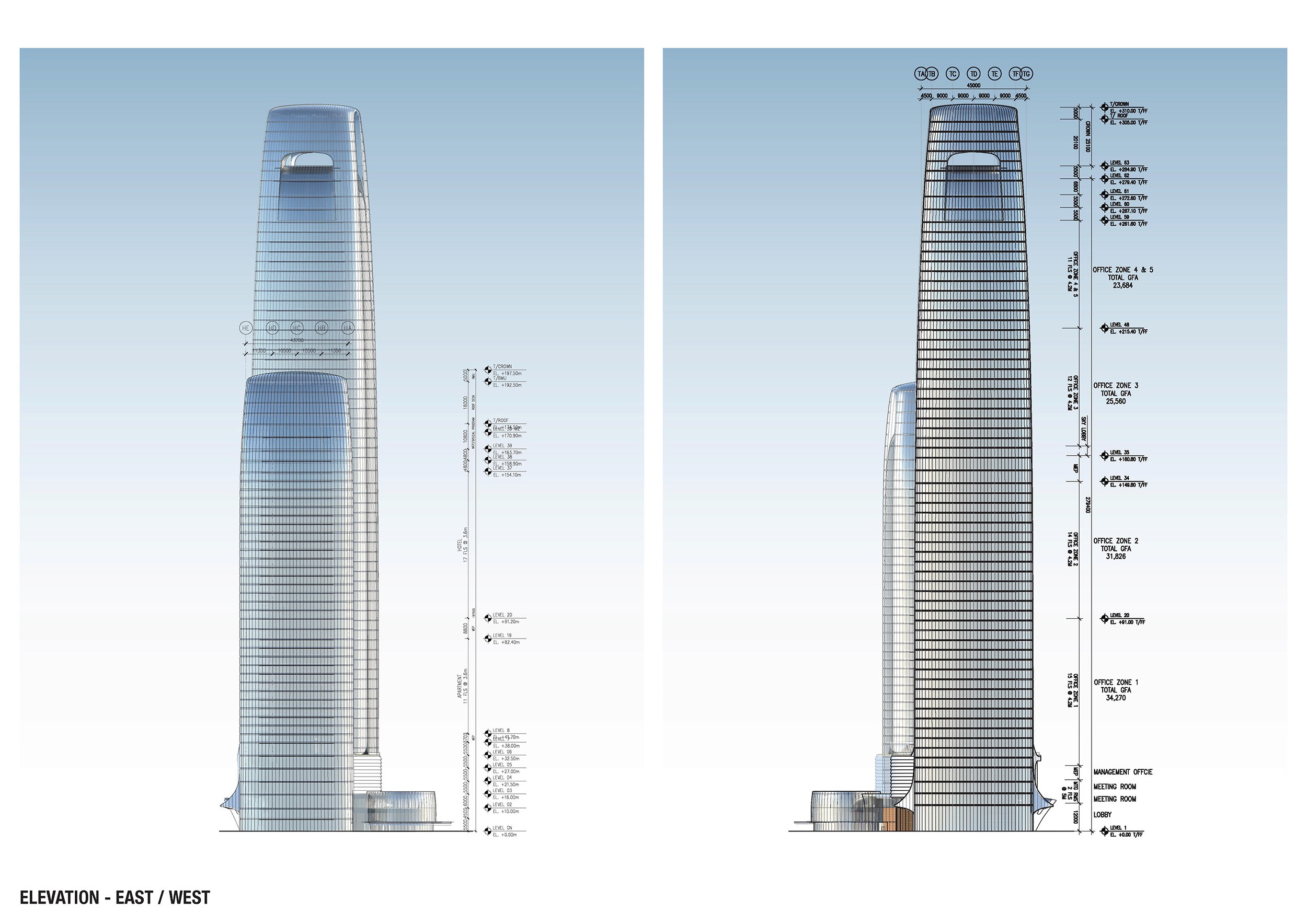

Proforma Validation & Building Massing

Proforma Validation & Building Massing

Proforma Validation & Building Massing

Facade Concept Ideation & Design

Facade Concept Ideation & Design

Facade Concept Ideation & Design

Sustainability Proof of Concept & Solar Analysis

Sustainability Proof of Concept & Solar Analysis

Sustainability Proof of Concept & Solar Analysis

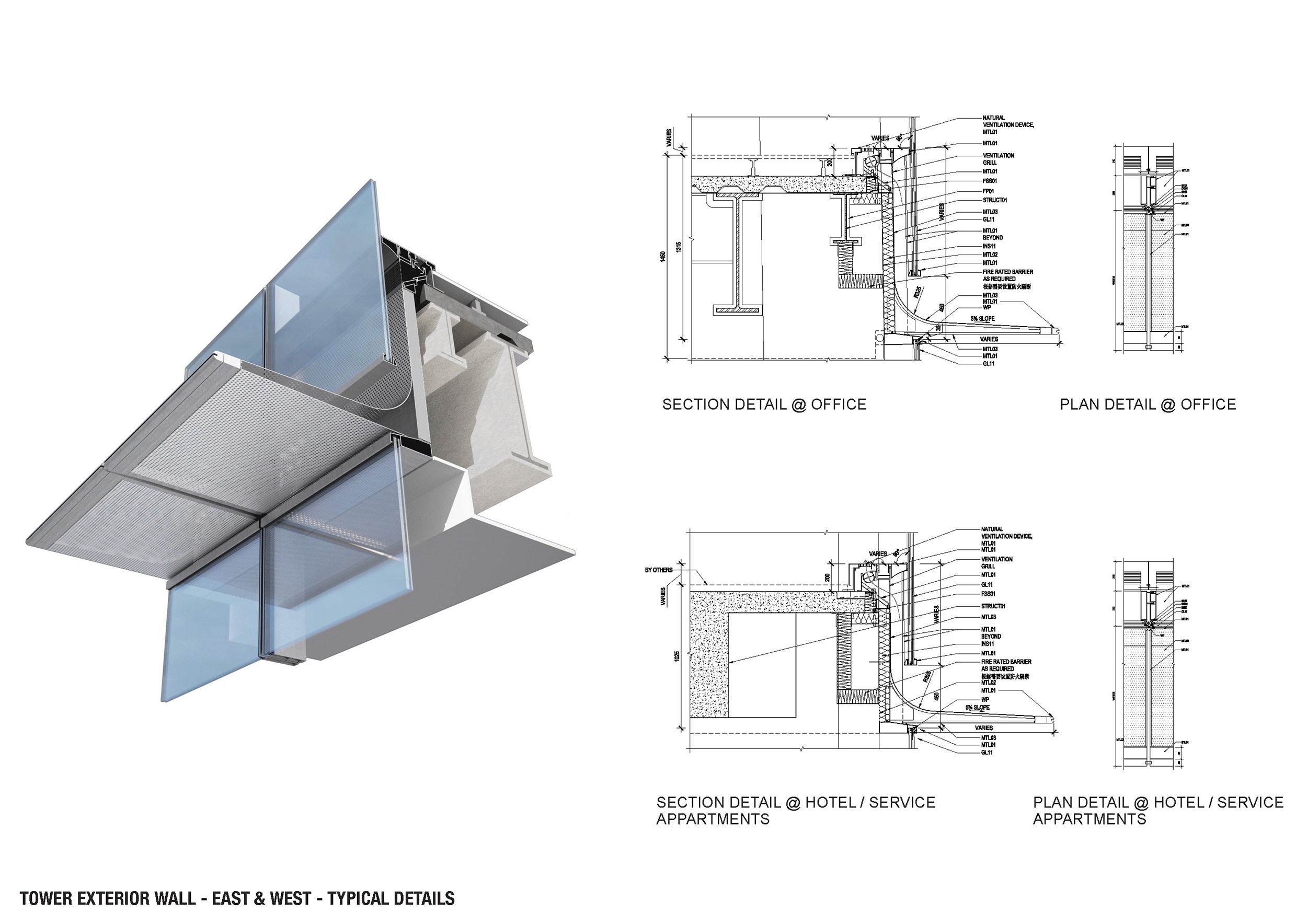

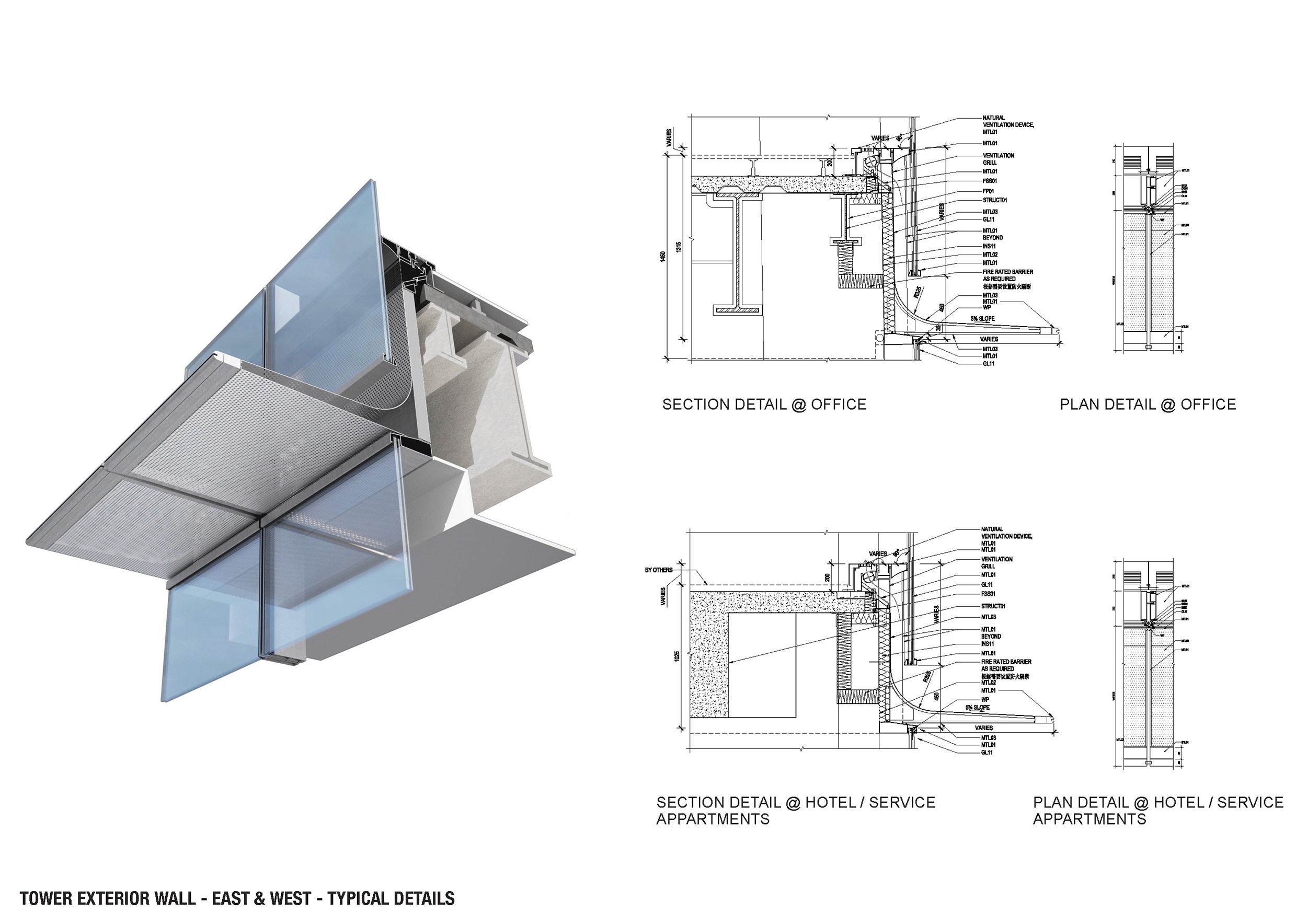

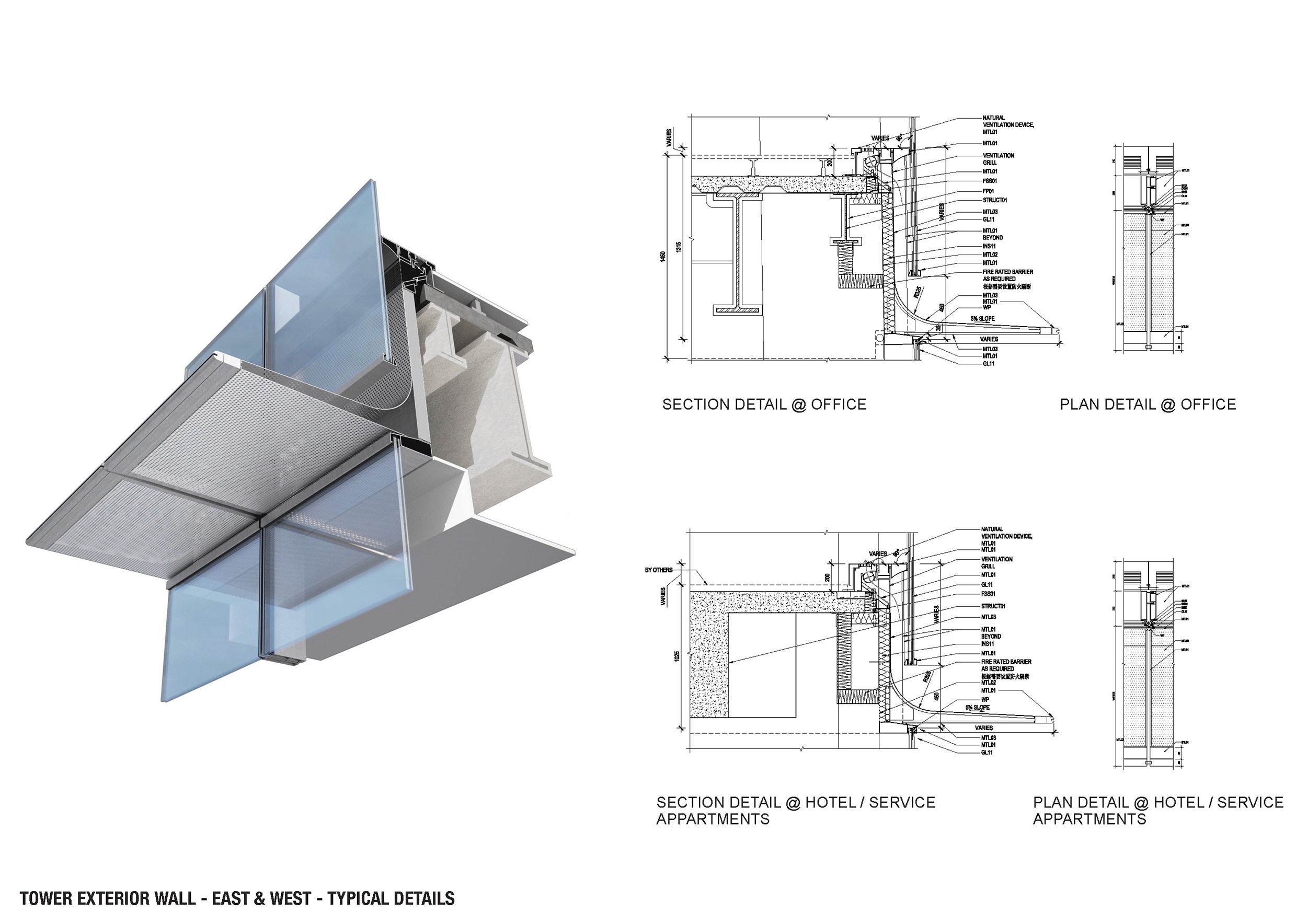

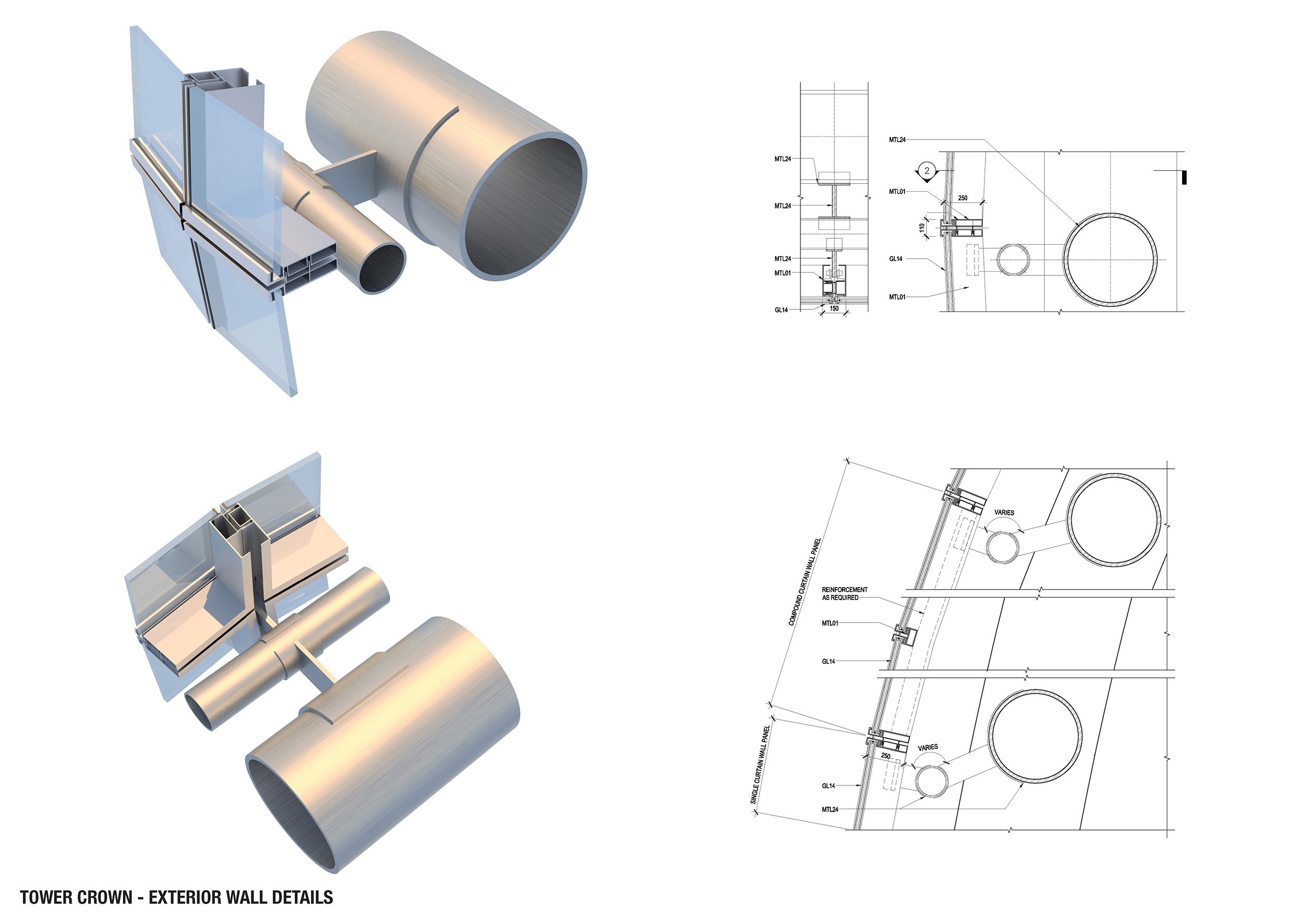

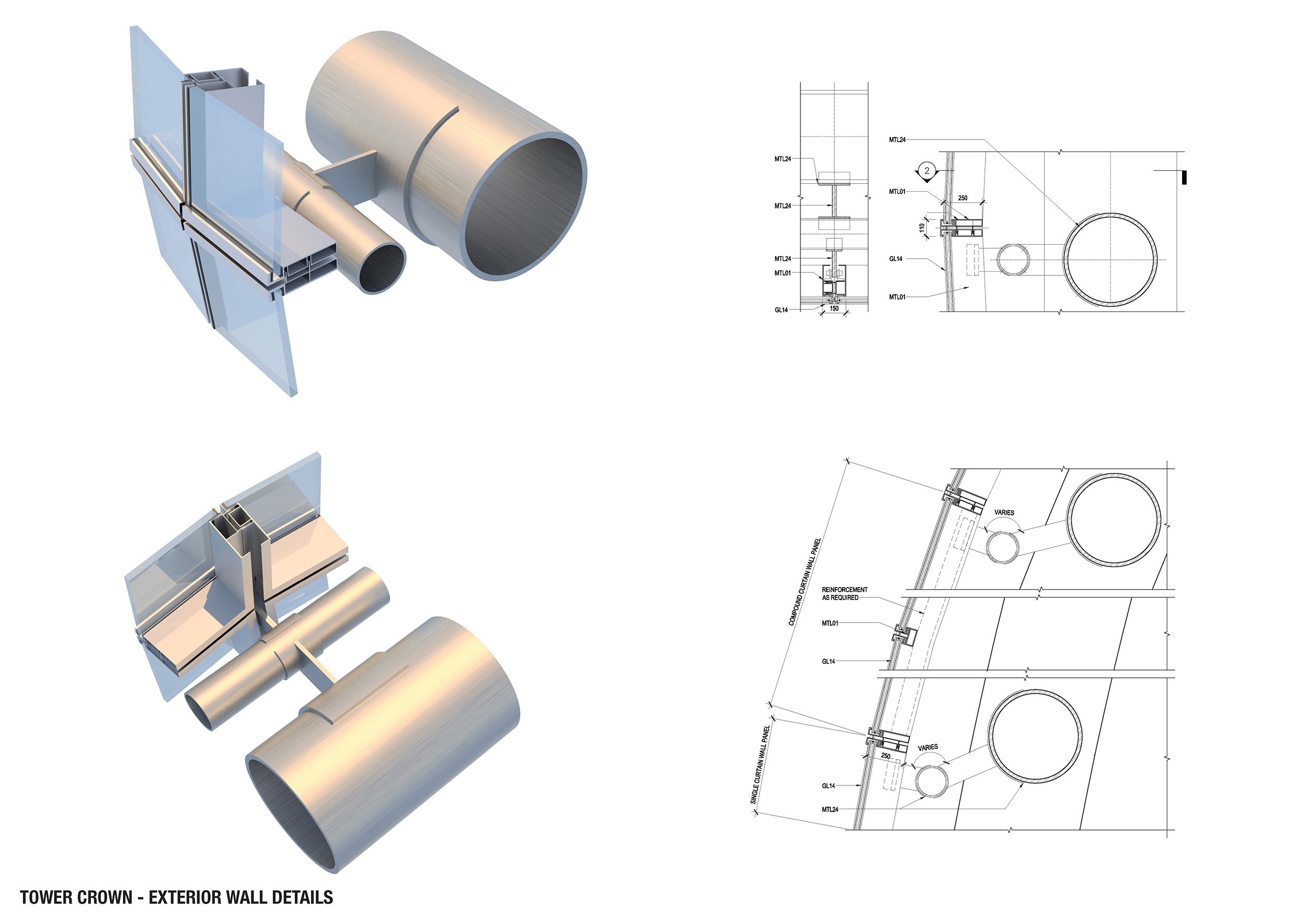

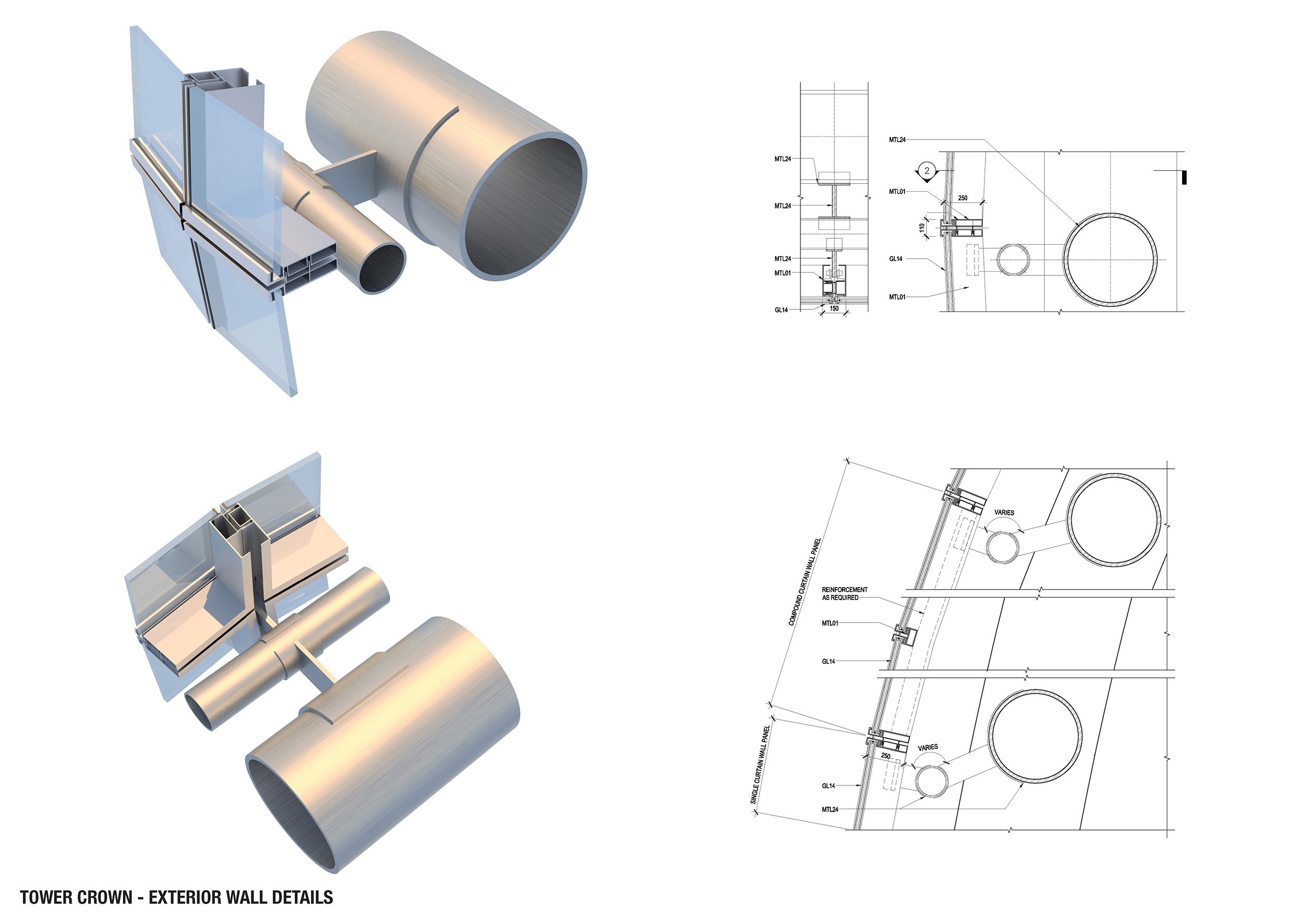

Technical Drawings / Vendor Management

Technical Drawings / Vendor Management

Technical Drawings / Vendor Management

(ML/W) Services

(ML/W) Services

(ML/W) Services

Architecture

Architecture

Architecture

Interior Design

Interior Design

Interior Design

Industrial Design & 3D Viz

Industrial Design & 3D Viz

Industrial Design & 3D Viz

Construction Documentation/Admin

Construction Documentation/Admin

01

DEFINE

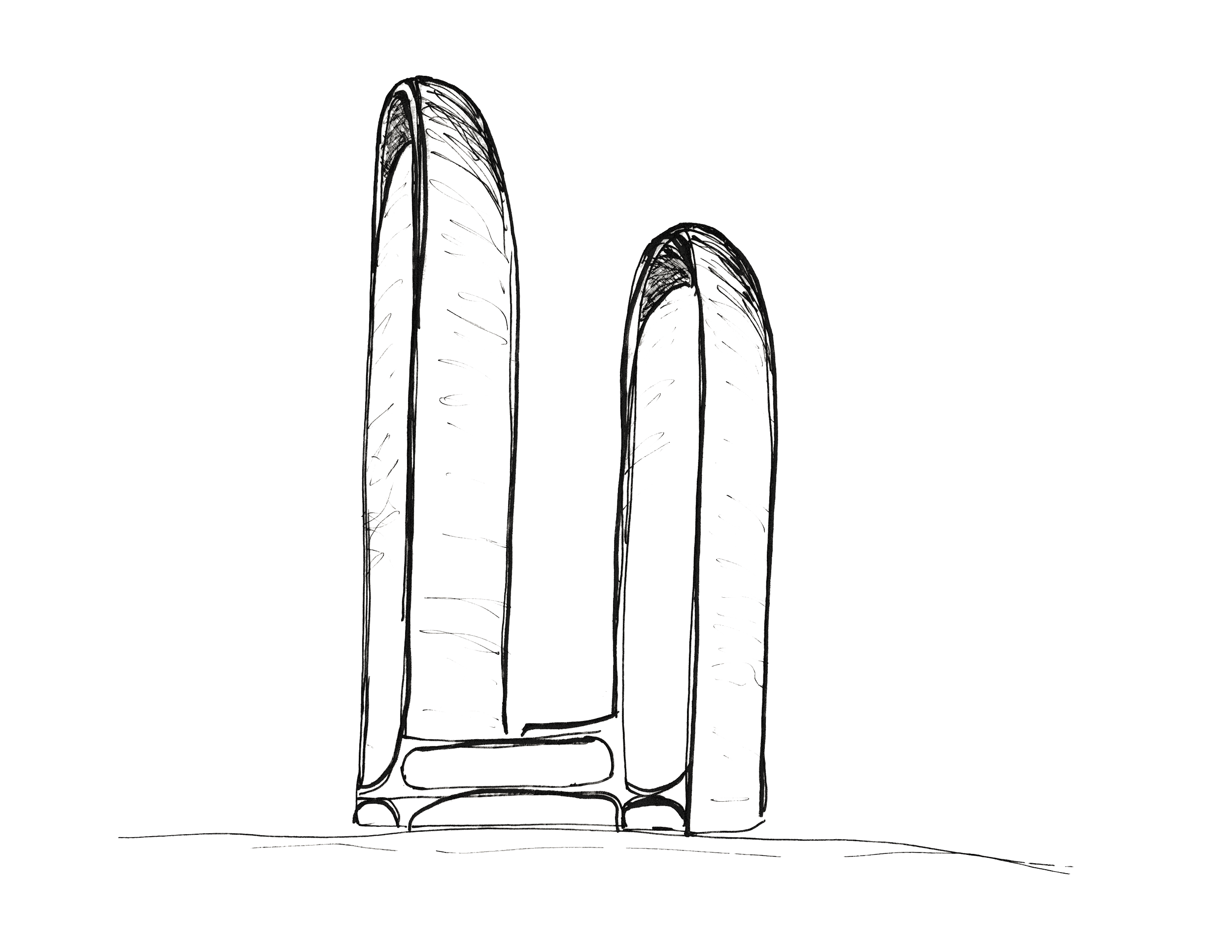

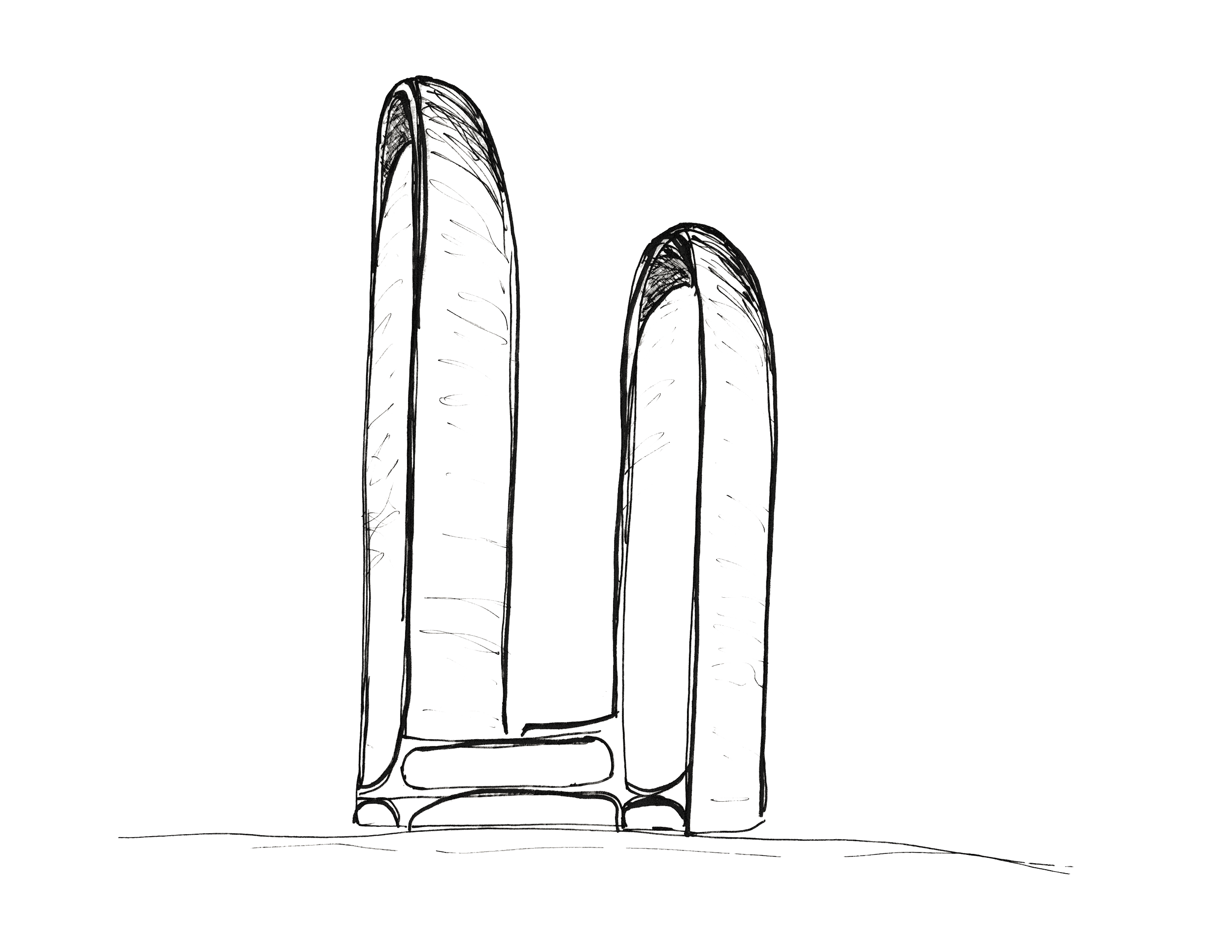

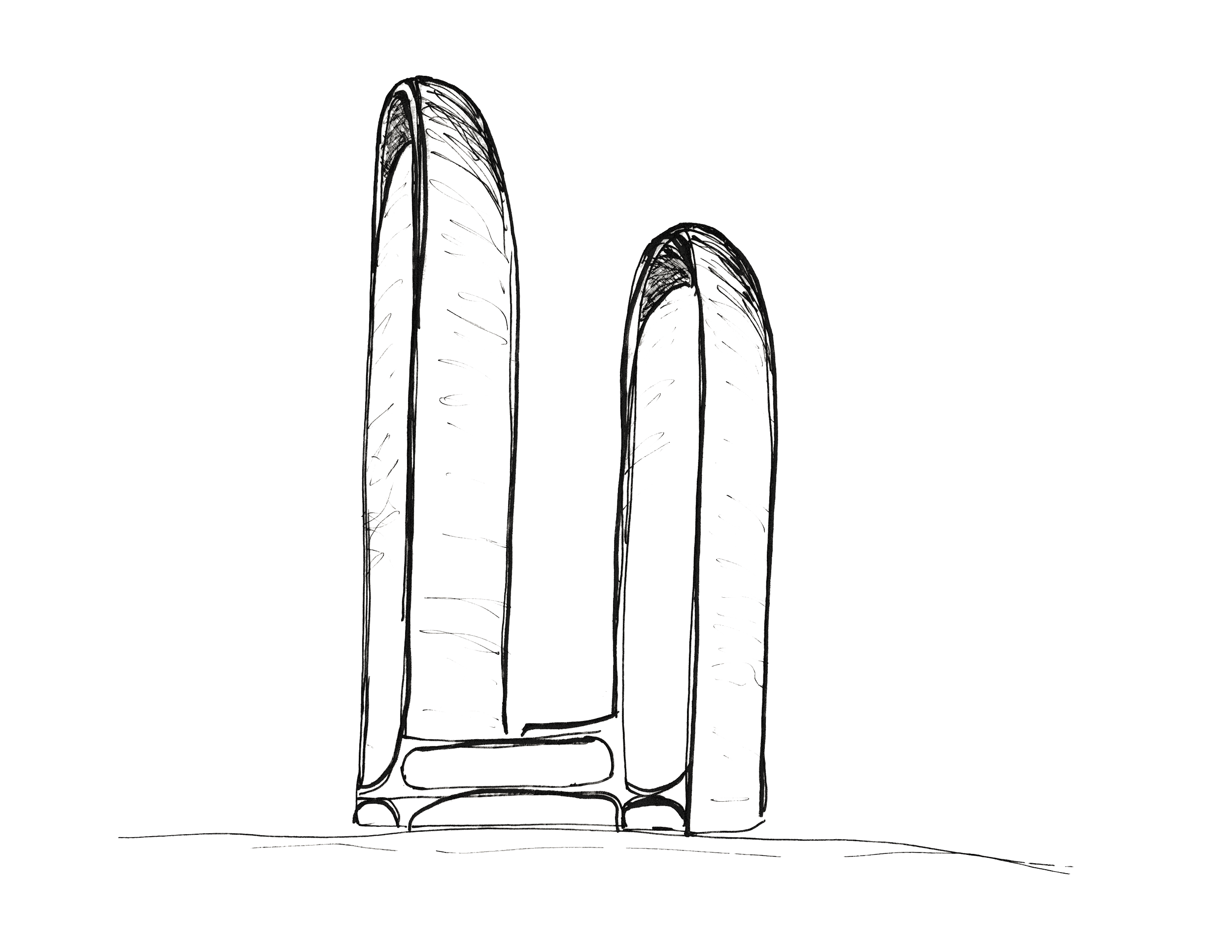

Form

Form

Form

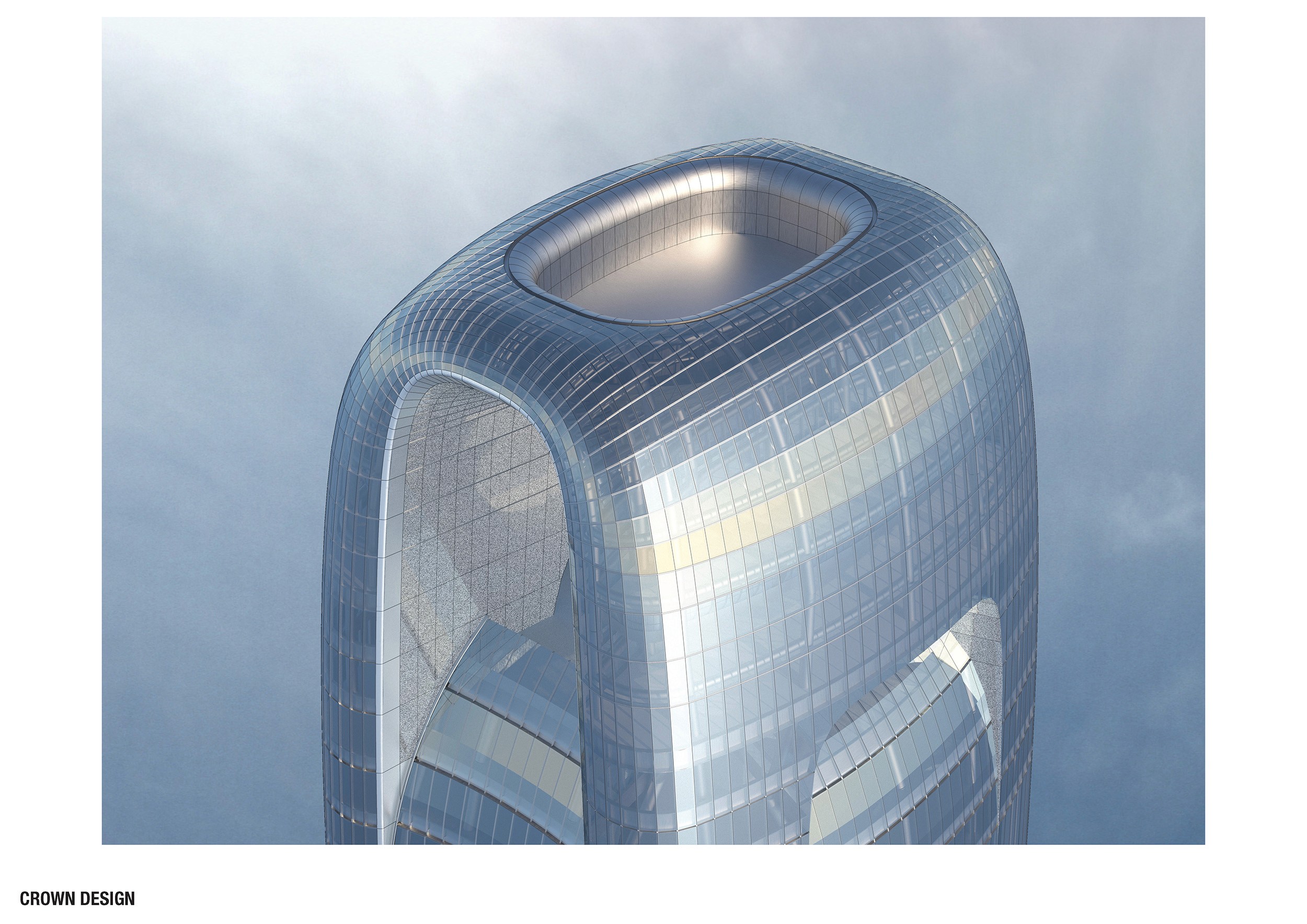

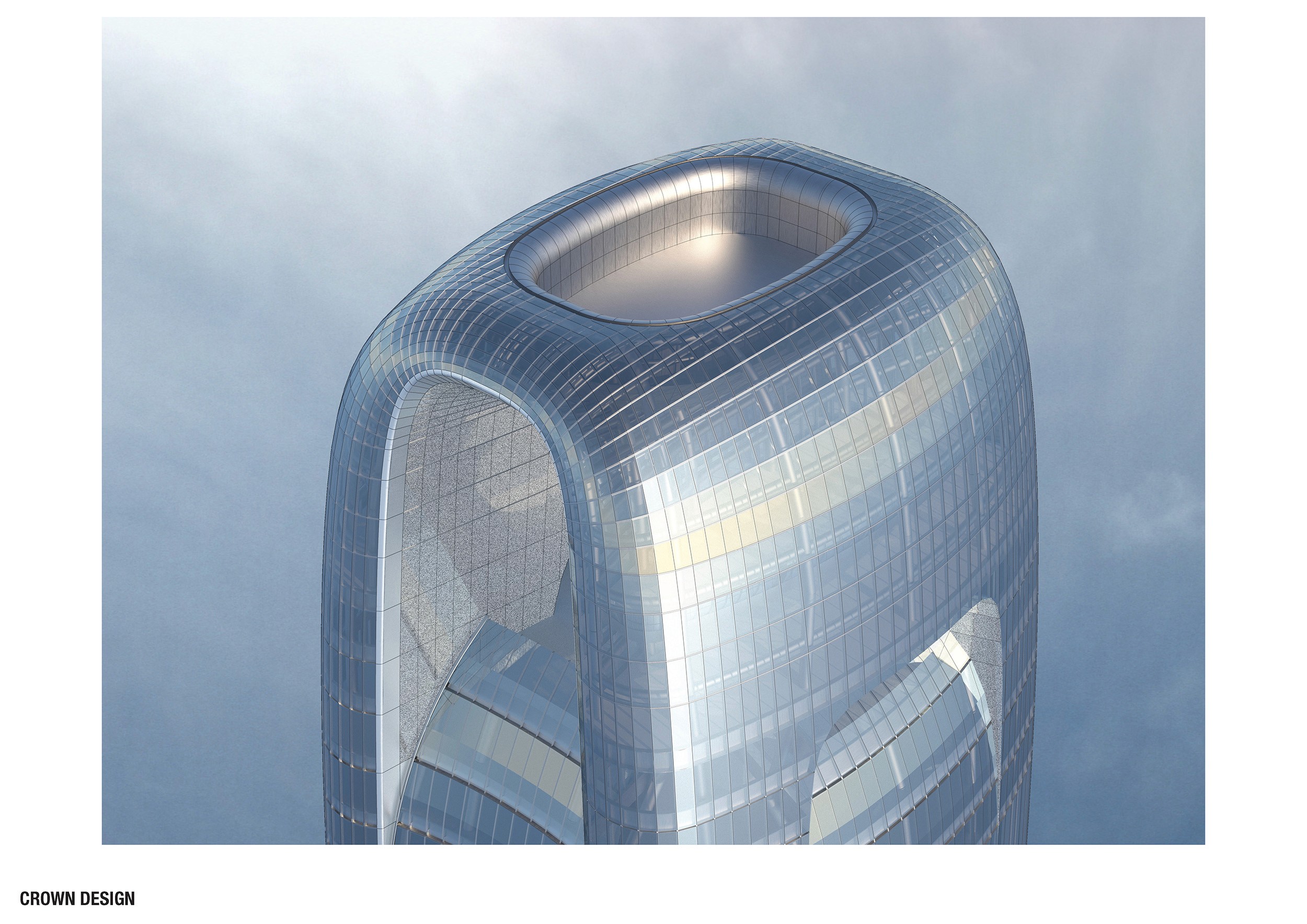

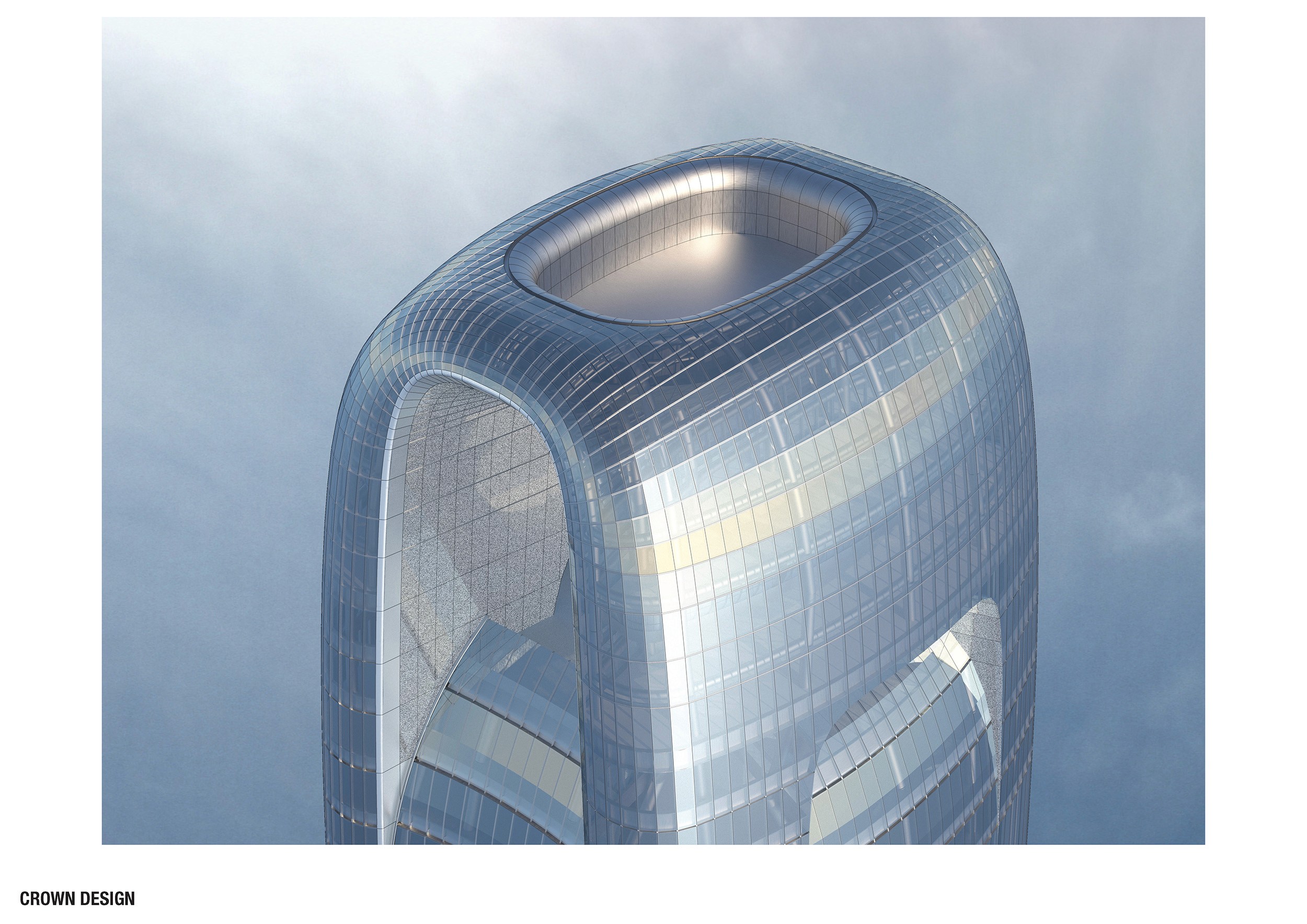

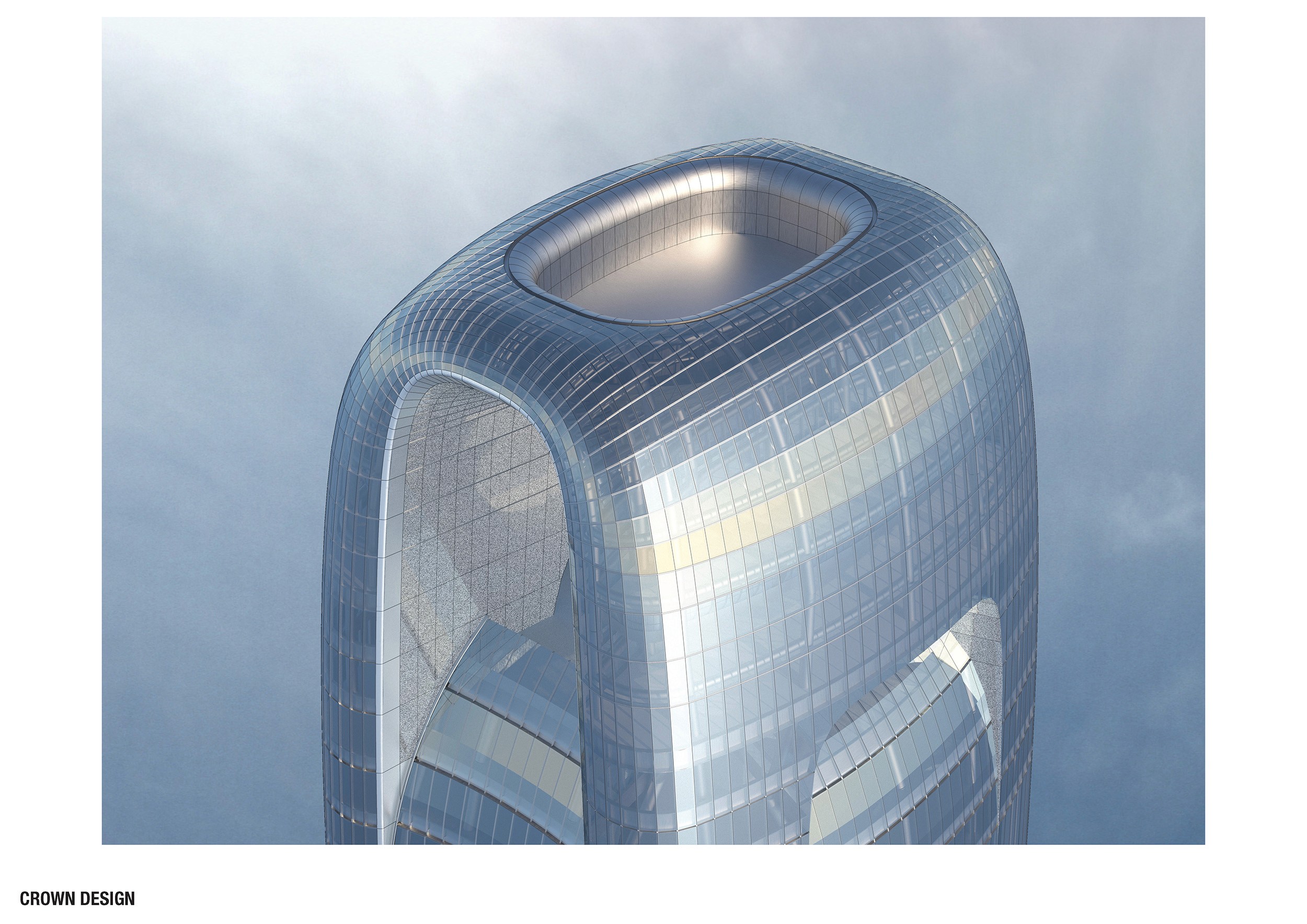

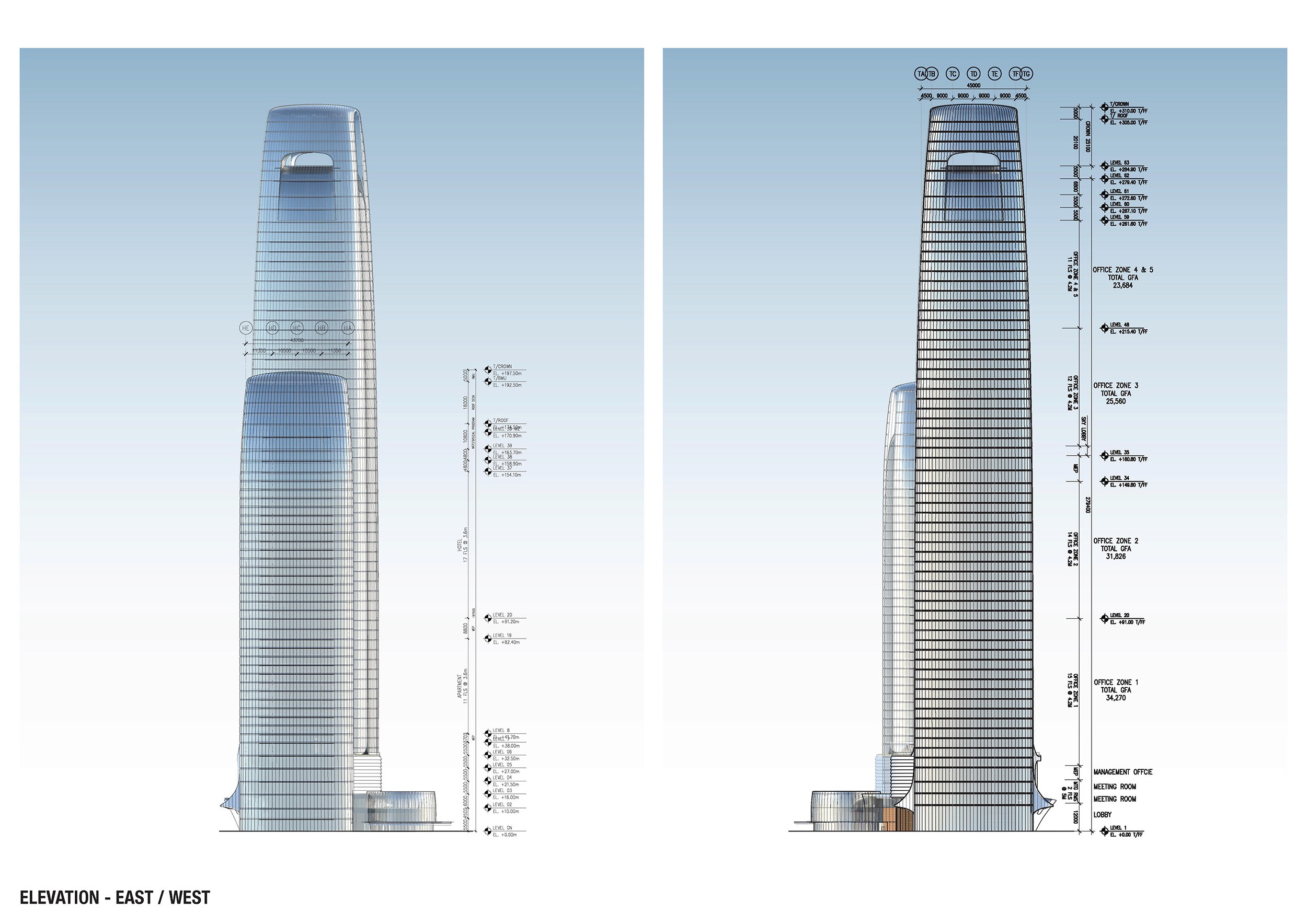

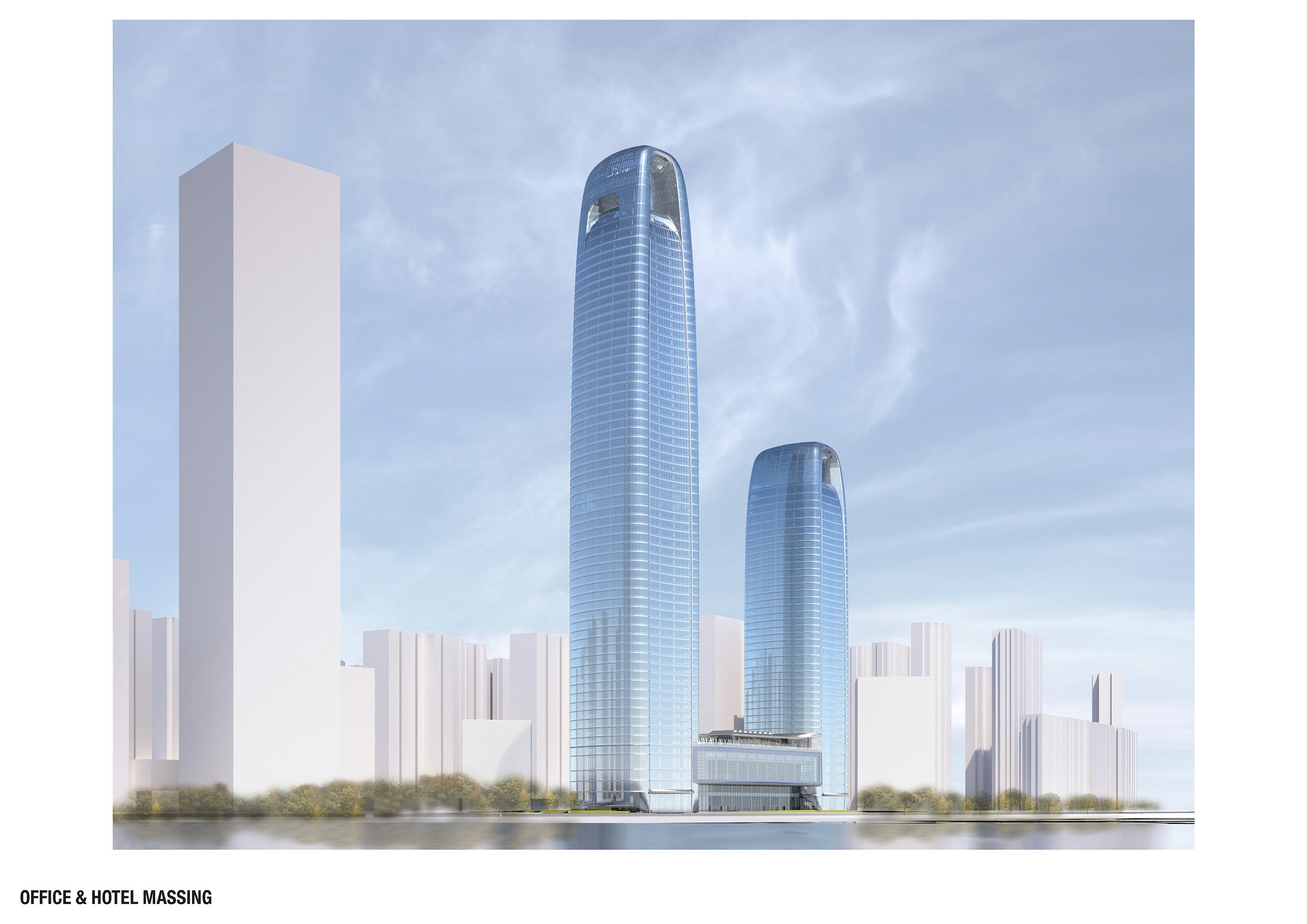

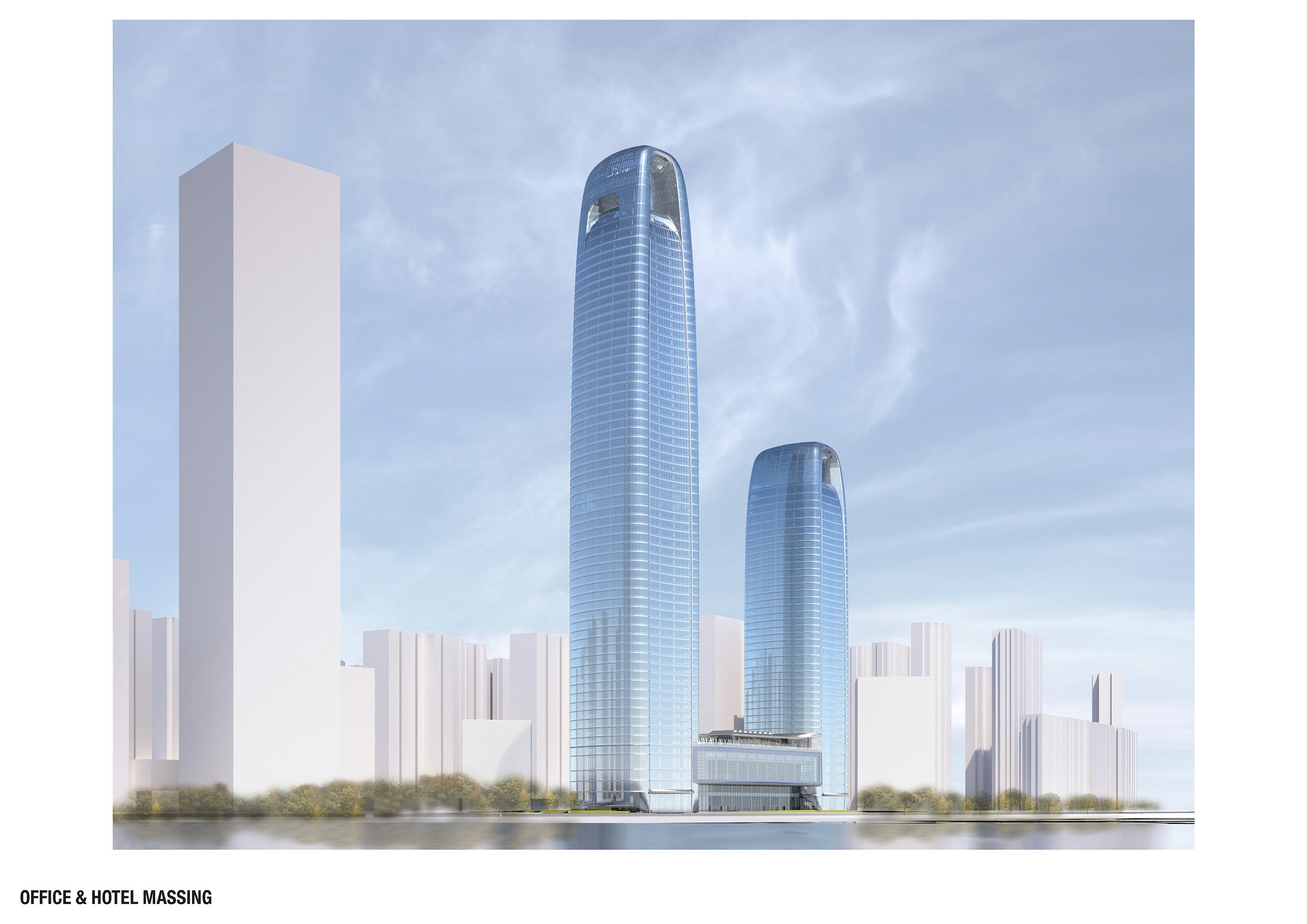

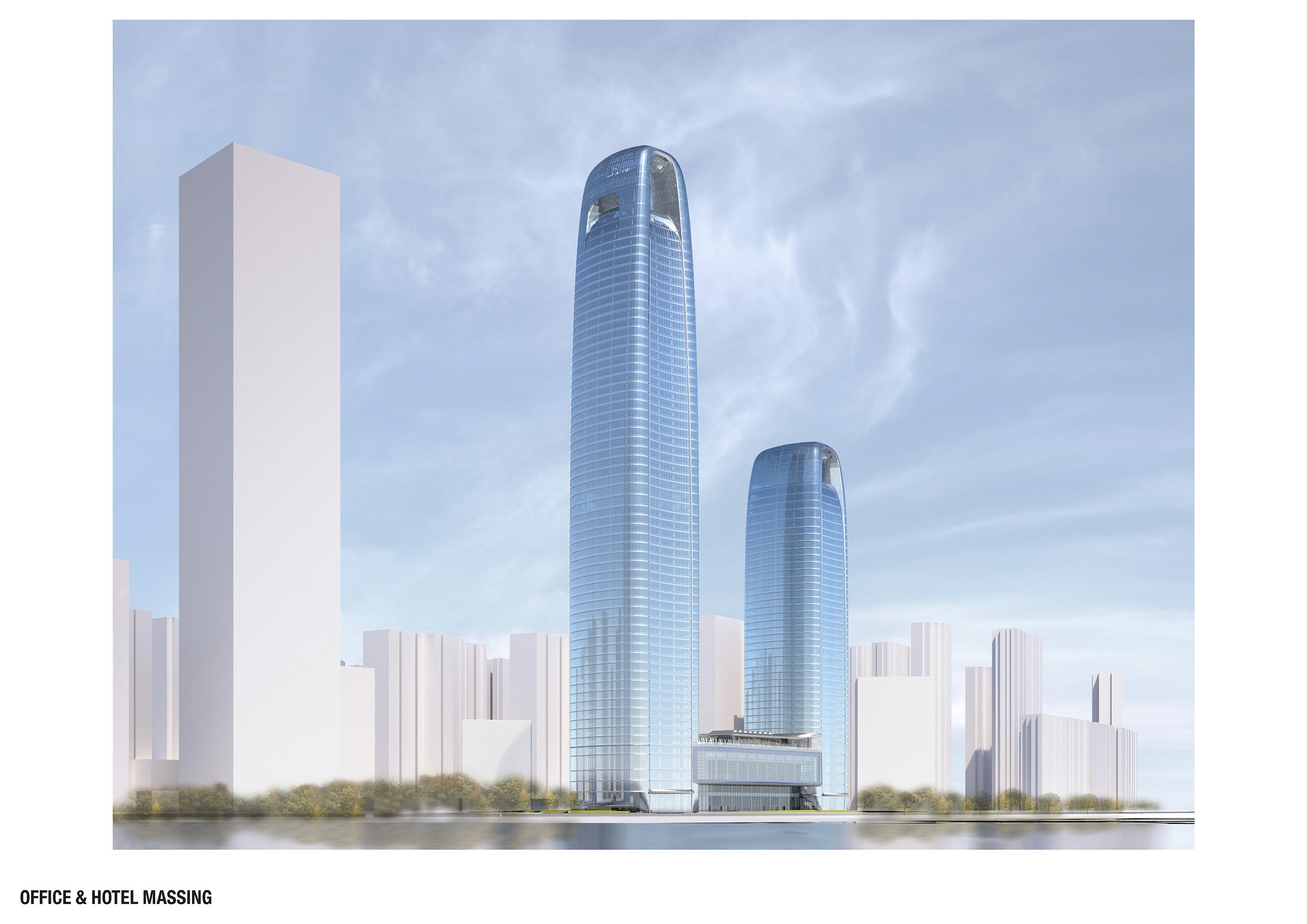

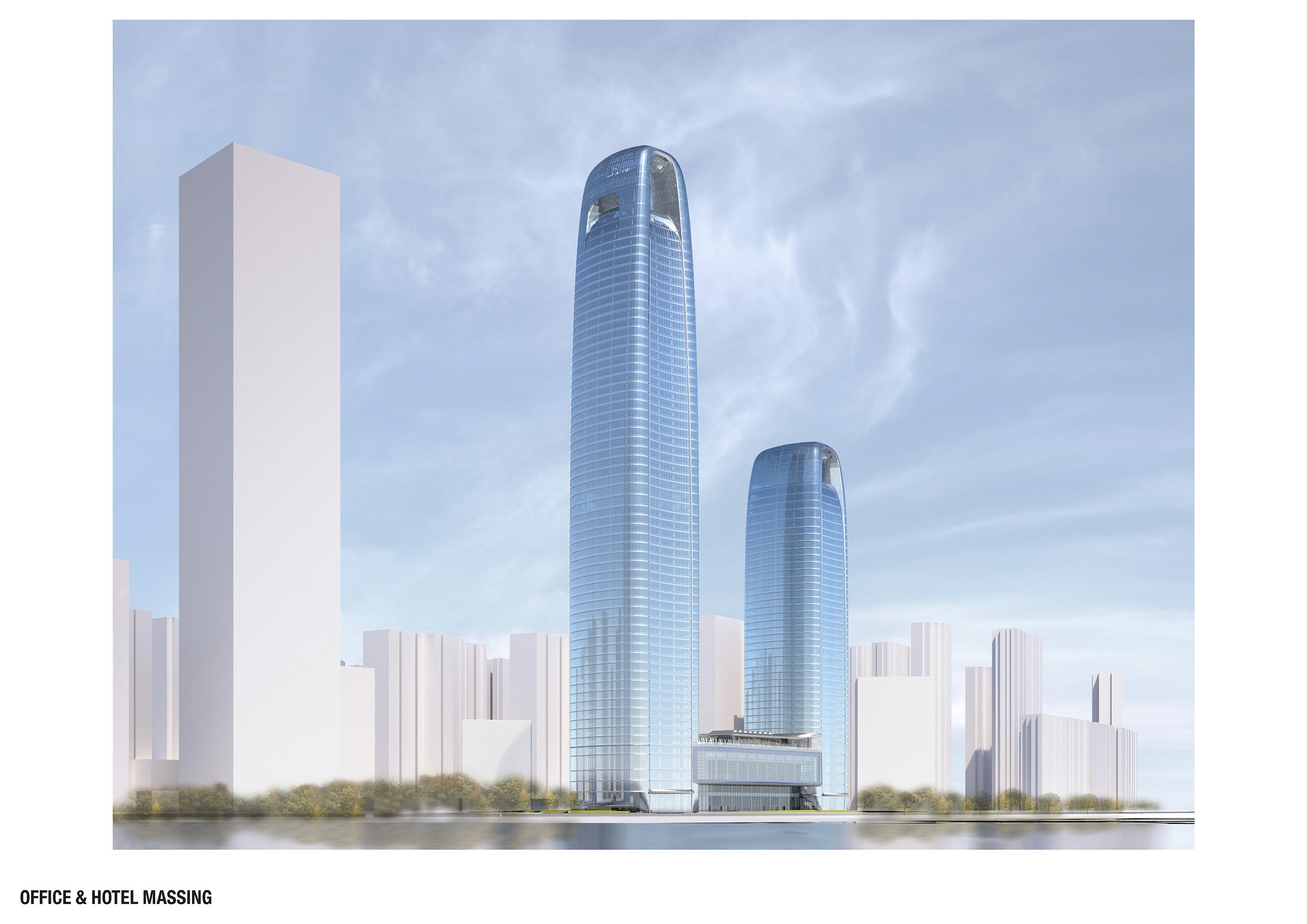

Massing for the 310m tower (office), 200M tower (hotel), and Podium (conference center/pool) buildings were created to maximize leasable area while adhering to site/FAR constraints, & proforma requirements.

Massing for the 310m tower (office), 200M tower (hotel), and Podium (conference center/pool) buildings were created to maximize leasable area while adhering to site/FAR constraints, & proforma requirements.

After a number of concept options were presented, Exterior wall fenestration that evoked the fluid nature of the site's waterfront while providing solar shading was selected by the client as the preferred design direction.

After a number of concept options were presented, Exterior wall fenestration that evoked the fluid nature of the site's waterfront while providing solar shading was selected by the client as the preferred design direction.

After a number of concept options were presented, Exterior wall fenestration that evoked the fluid nature of the site's waterfront while providing solar shading was selected by the client as the preferred design direction.

02

ENVIRONMENTAL

Analysis

Analysis

Analysis

ML/W created custom software routines using Autodesk ecotect, rhino, & the visual programming tool grasshopper to automate analysis of Environmental performance at both the curtain wall module & building level.

ML/W created custom software routines using Autodesk ecotect, rhino, & the visual programming tool grasshopper to automate analysis of Environmental performance at both the curtain wall module & building level.

ML/W created custom software routines using Autodesk ecotect, rhino, & the visual programming tool grasshopper to automate analysis of Environmental performance at both the curtain wall module & building level.

The results informed the desired exterior wall shading devices, optimizing the angle & depth relative to geographical location & reduction in solar radiation on an average annualized basis.

The results informed the desired exterior wall shading devices, optimizing the angle & depth relative to geographical location & reduction in solar radiation on an average annualized basis.

The results informed the desired exterior wall shading devices, optimizing the angle & depth relative to geographical location & reduction in solar radiation on an average annualized basis.

additional Exterior wall shading options were studied in parallel in pursuit of a version that blended solar heat gain reduction across all facade exposures, wind resistance, material cost, & economy of scale for the curtain wall manufacturer.

additional Exterior wall shading options were studied in parallel in pursuit of a version that blended solar heat gain reduction across all facade exposures, wind resistance, material cost, & economy of scale for the curtain wall manufacturer.

additional Exterior wall shading options were studied in parallel in pursuit of a version that blended solar heat gain reduction across all facade exposures, wind resistance, material cost, & economy of scale for the curtain wall manufacturer.

03

REFINE

Details

Details

Details

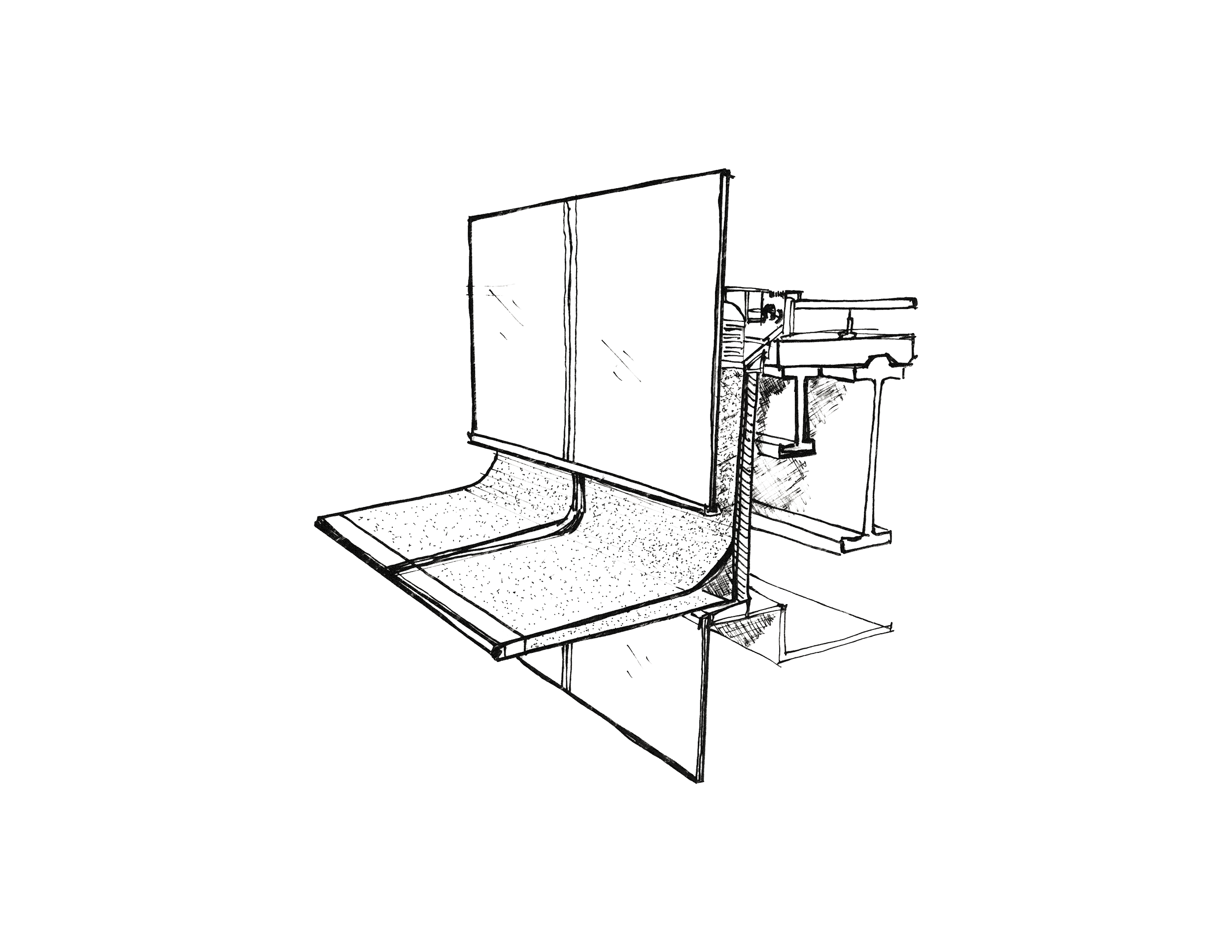

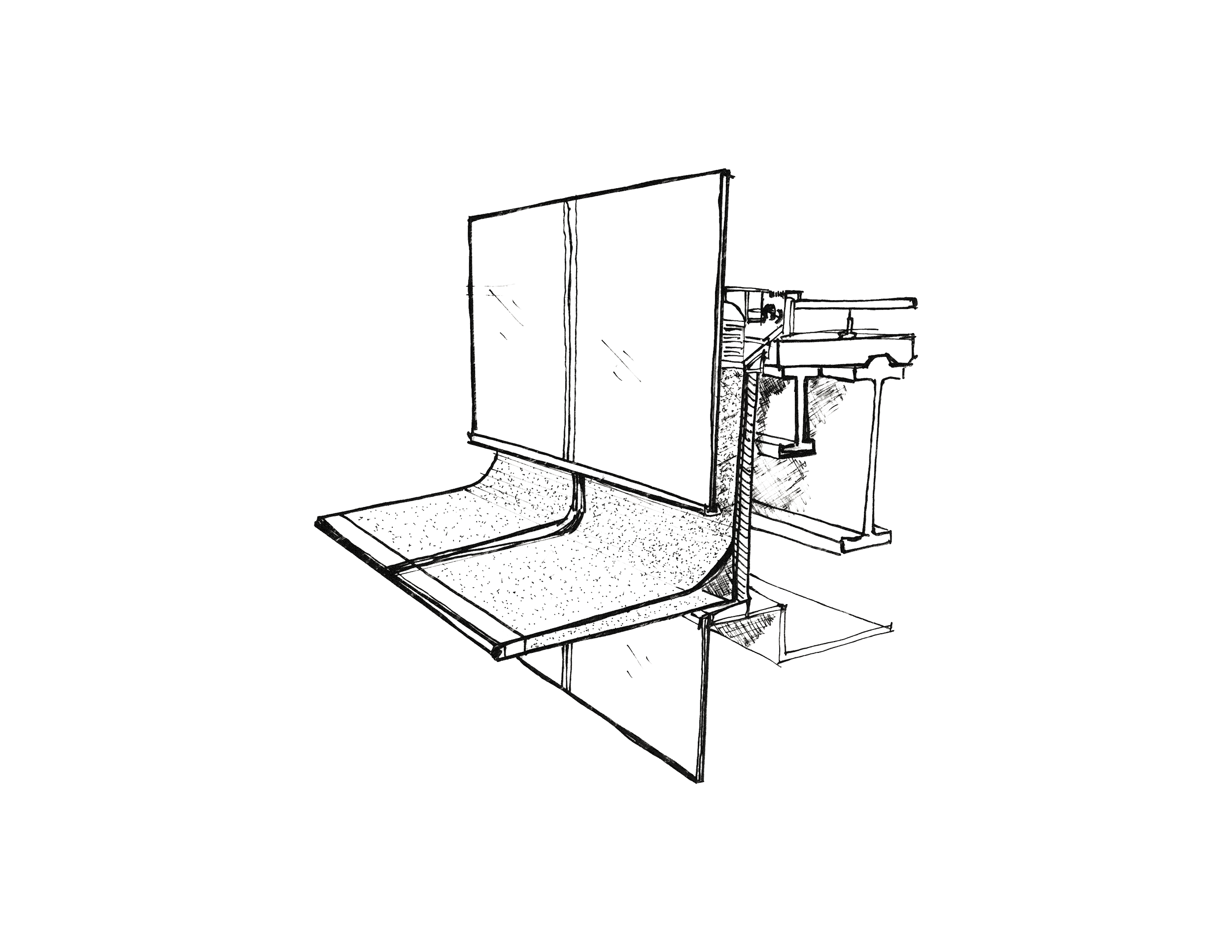

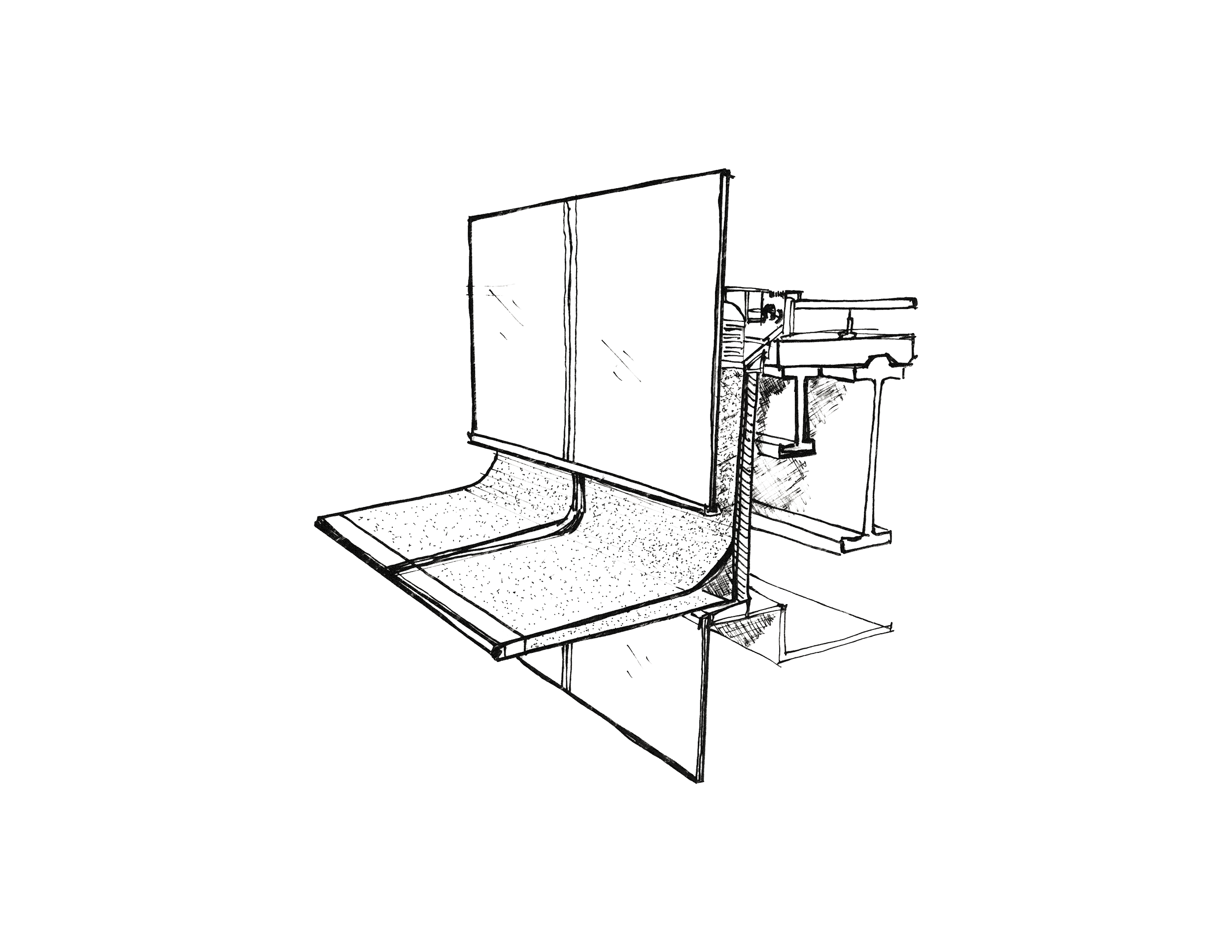

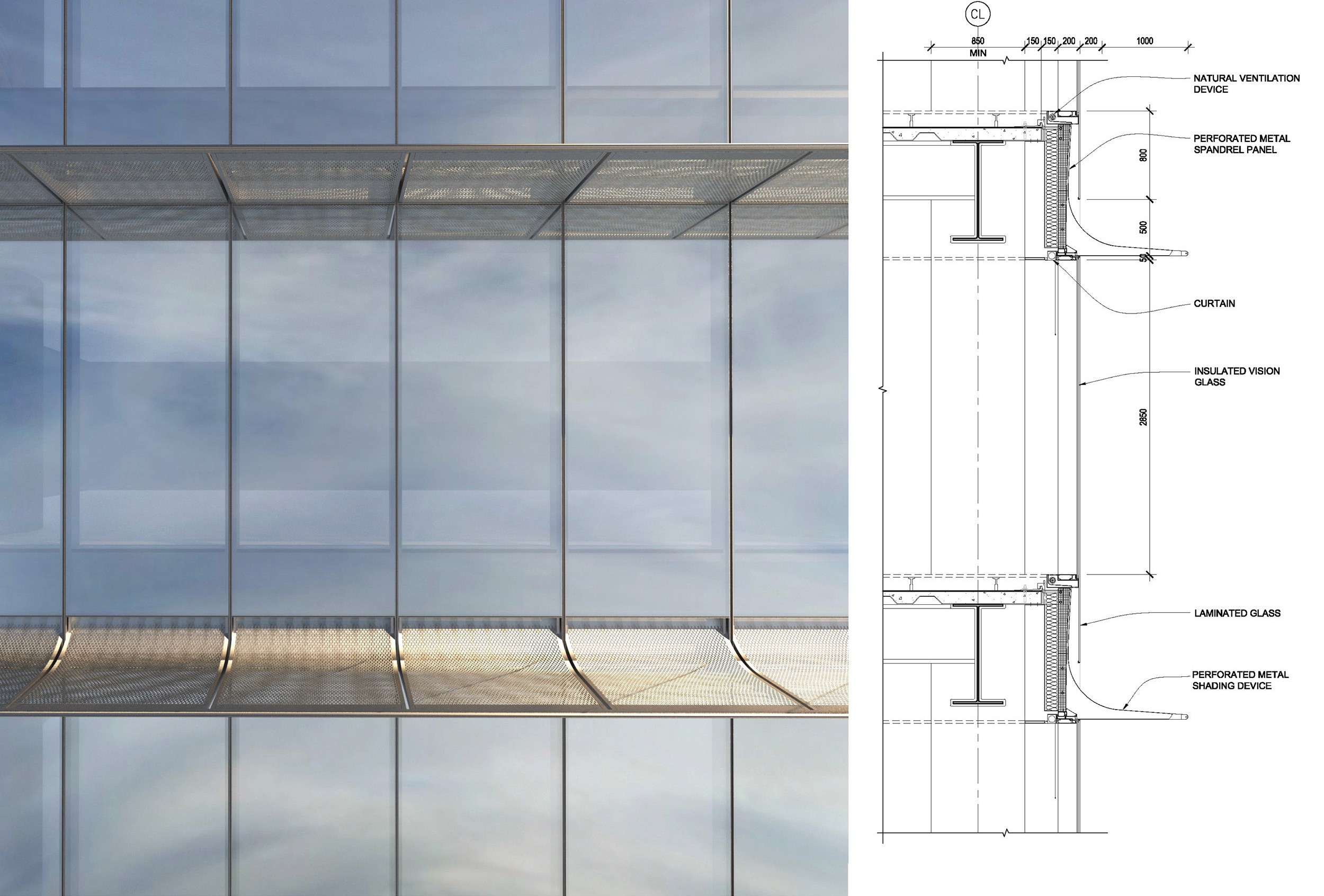

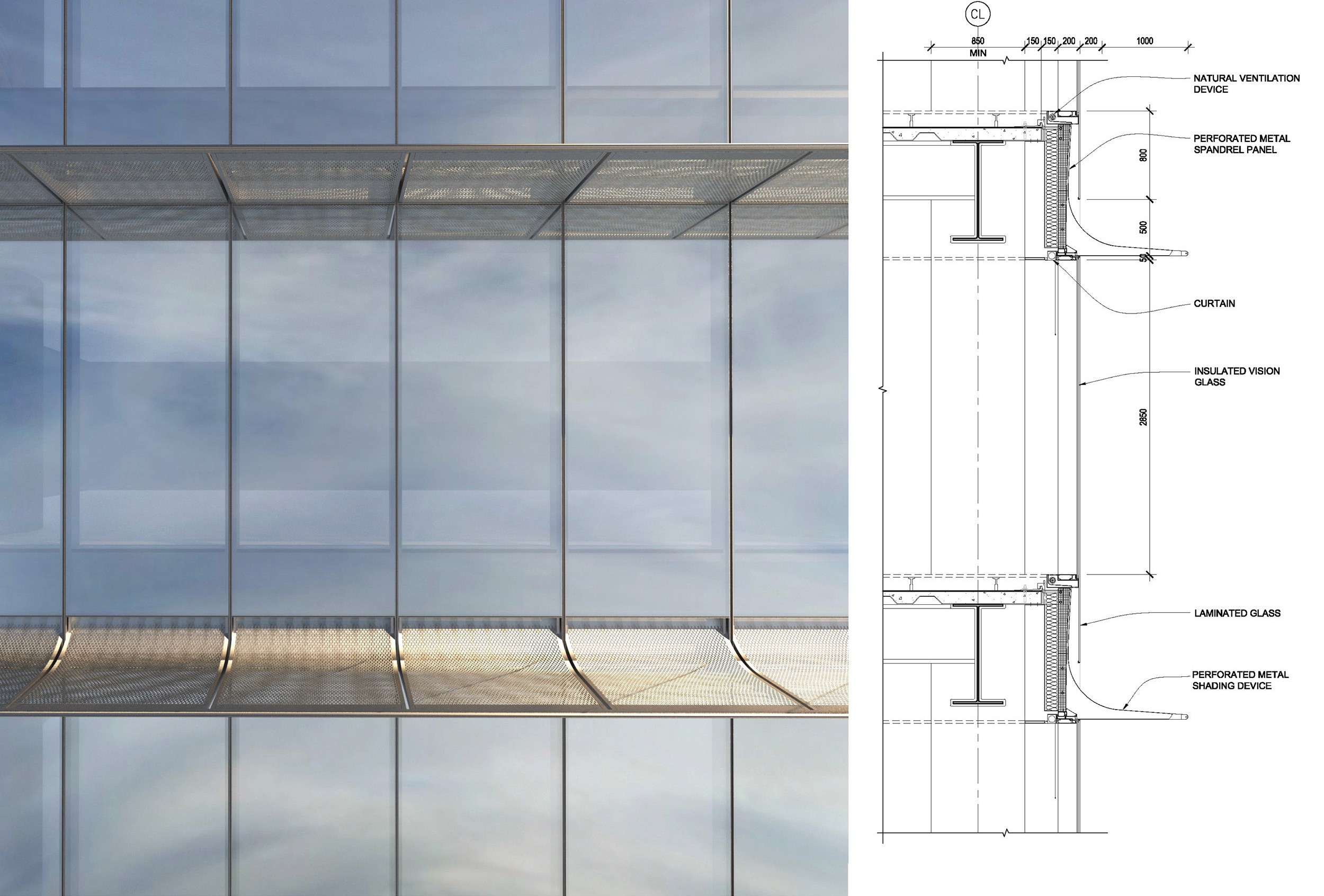

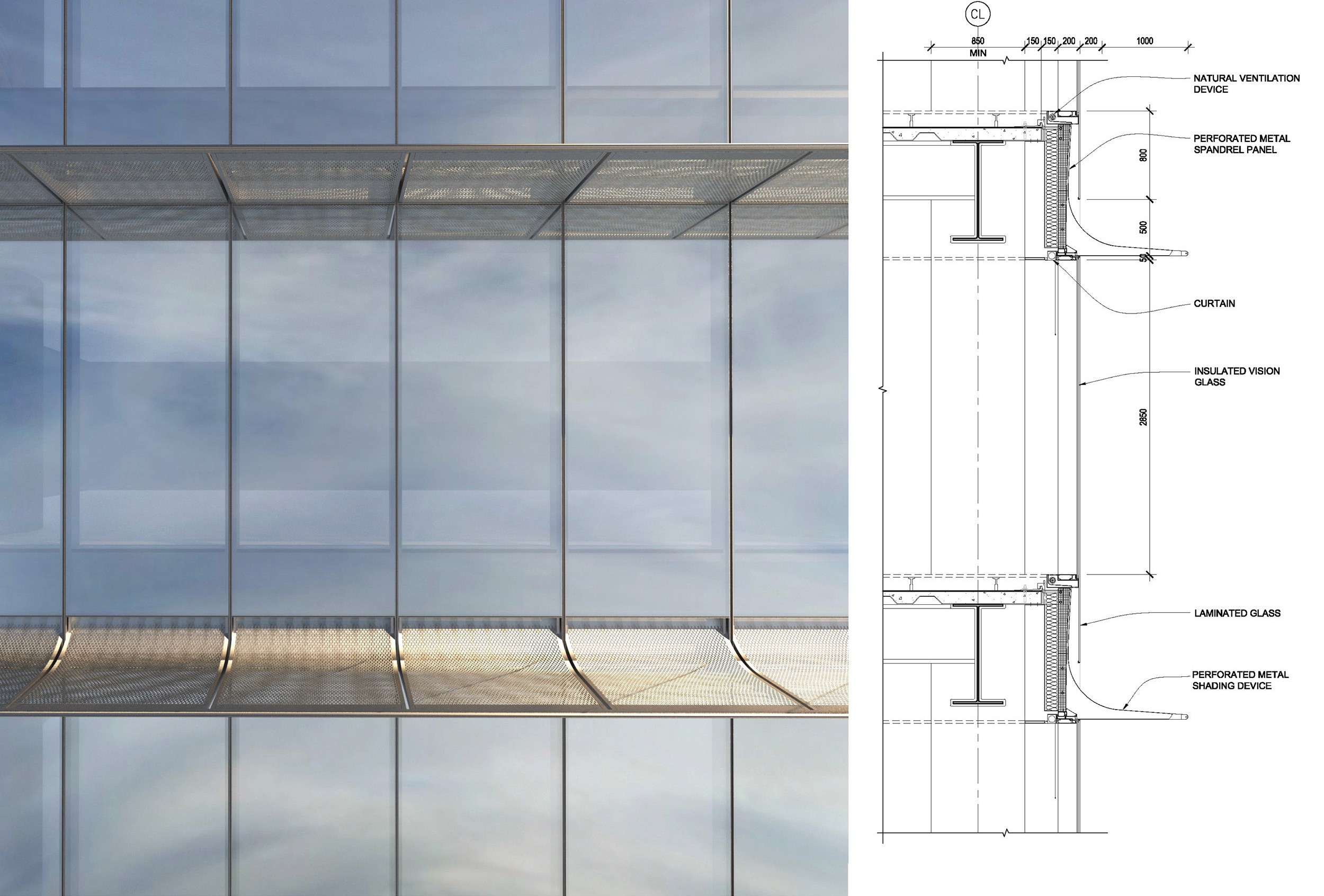

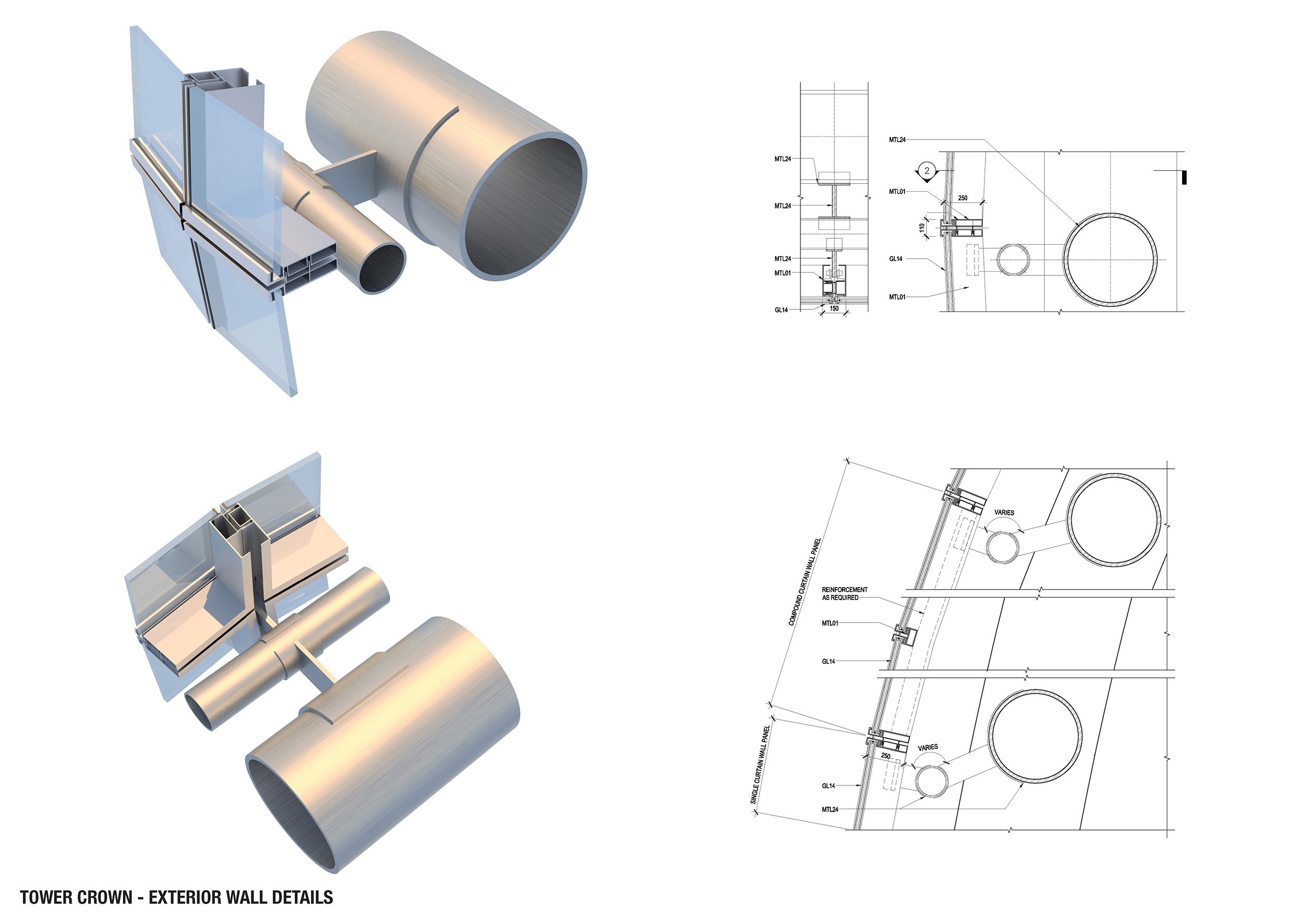

Following many interations, ML/W proposed a curtain wall system with a typical module that used a single, continuous igu (insulated glass unit) & an exterior shading device made of perforated metal, which was approved by both the client & SOM leadership.

Following many interations, ML/W proposed a curtain wall system with a typical module that used a single, continuous igu (insulated glass unit) & an exterior shading device made of perforated metal, which was approved by both the client & SOM leadership.

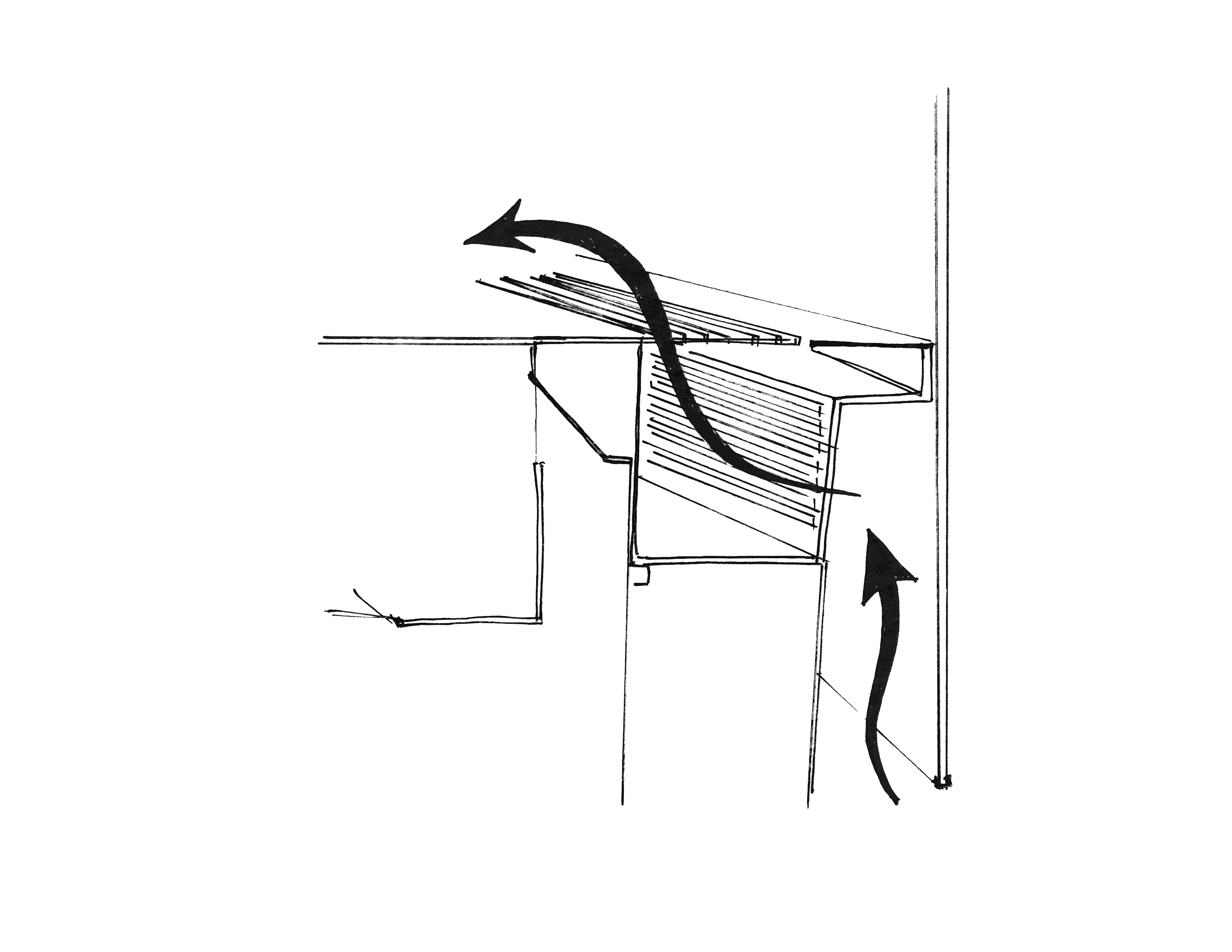

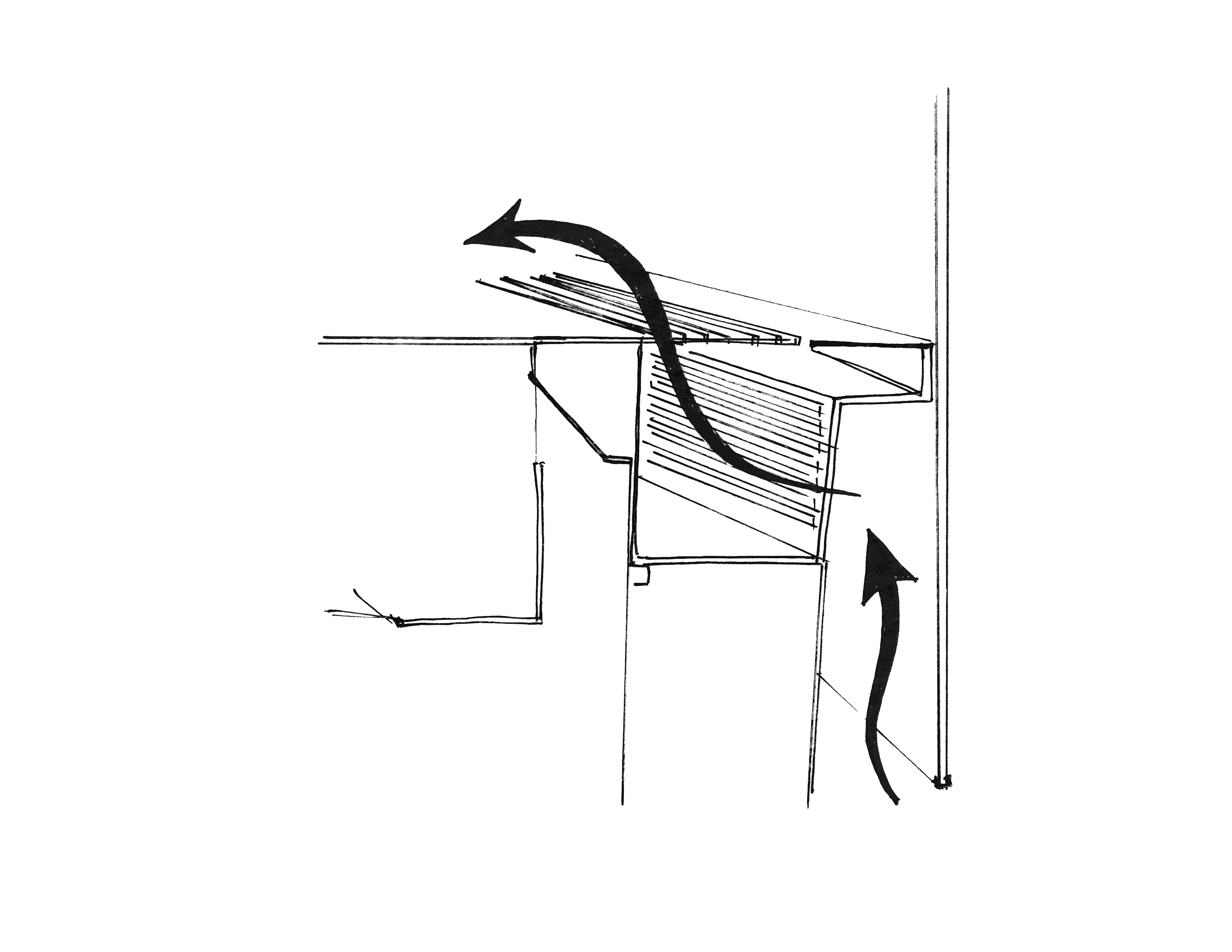

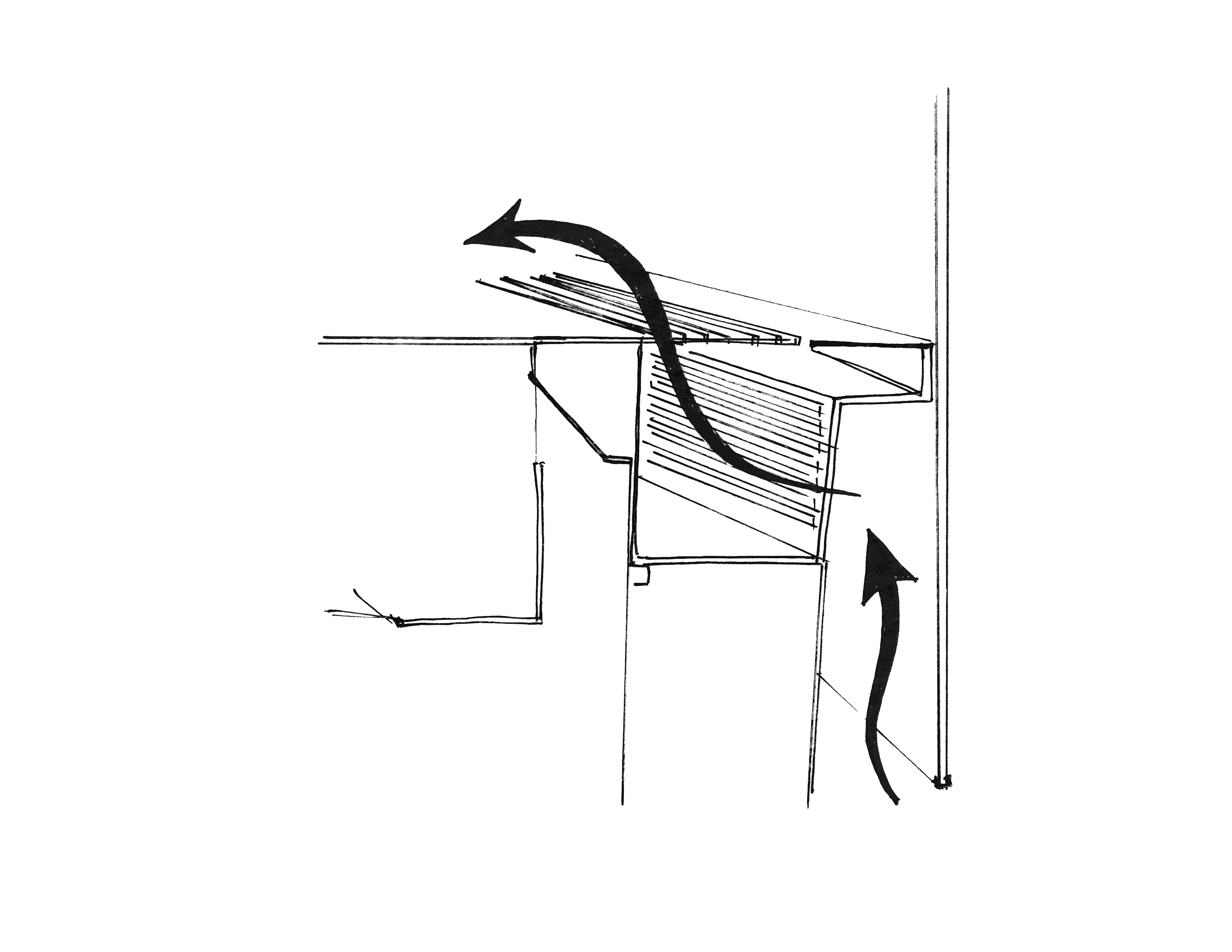

ML/W's design integrated A "vented" mullion above the exterior shading device that allowed for natural ventilation without the need for operable windows.

ML/W's design integrated A "vented" mullion above the exterior shading device that allowed for natural ventilation without the need for operable windows.

ML/W's design integrated A "vented" mullion above the exterior shading device that allowed for natural ventilation without the need for operable windows.

Solar analysis confirmed a 21% reduction in Average Daily Radiation from the control study (facade with no shading device).

Combined with the use of natural ventilation, in-house energy model results estimated a 4.4% reduction in overall building energy consumption annually.

Solar analysis confirmed a 21% reduction in Average Daily Radiation from the control study (facade with no shading device).

Combined with the use of natural ventilation, in-house energy model results estimated a 4.4% reduction in overall building energy consumption annually.

Solar analysis confirmed a 21% reduction in Average Daily Radiation from the control study (facade with no shading device).

Combined with the use of natural ventilation, in-house energy model results estimated a 4.4% reduction in overall building energy consumption annually.

04

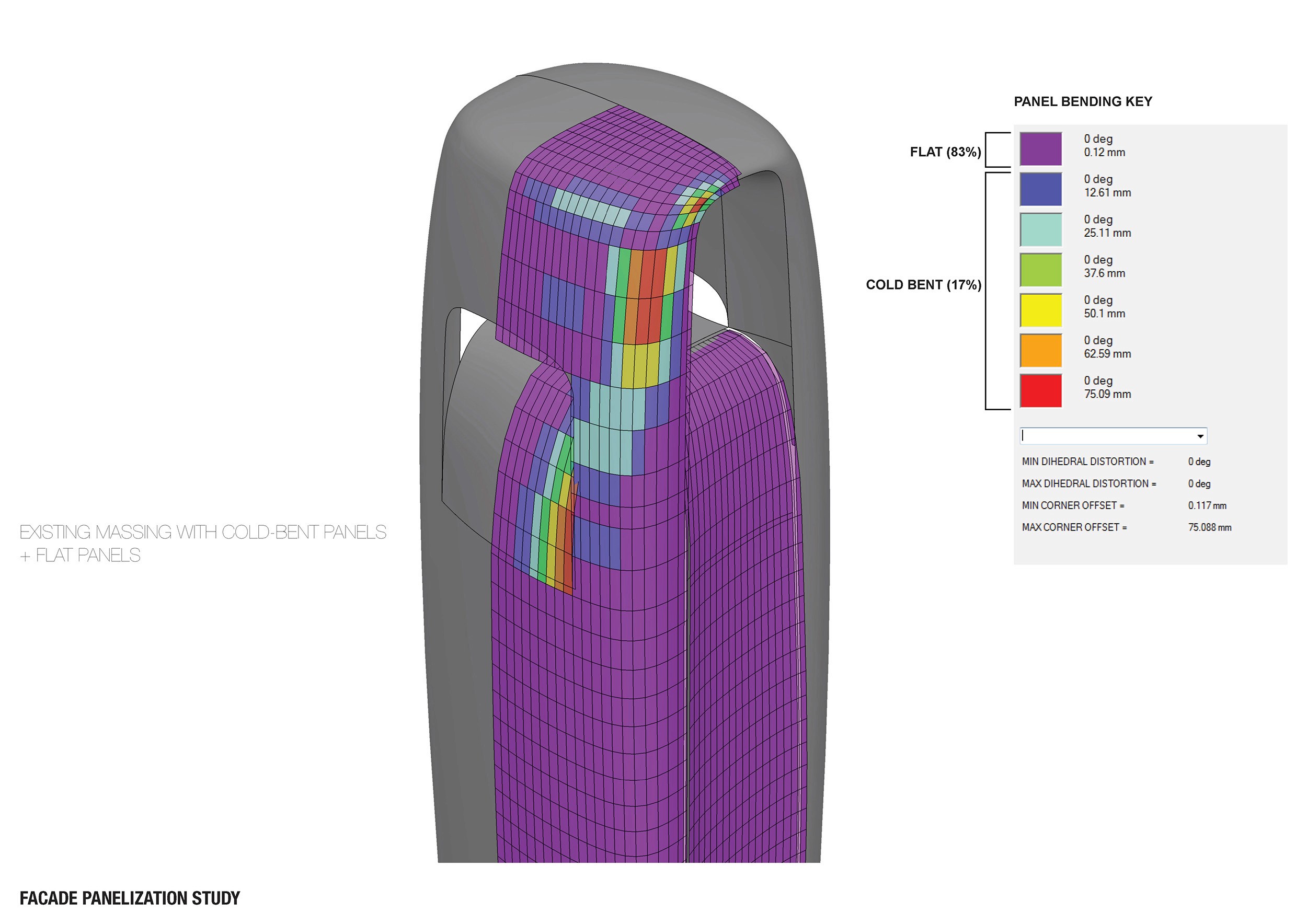

GEOMETRY

optimization

optimization

optimization

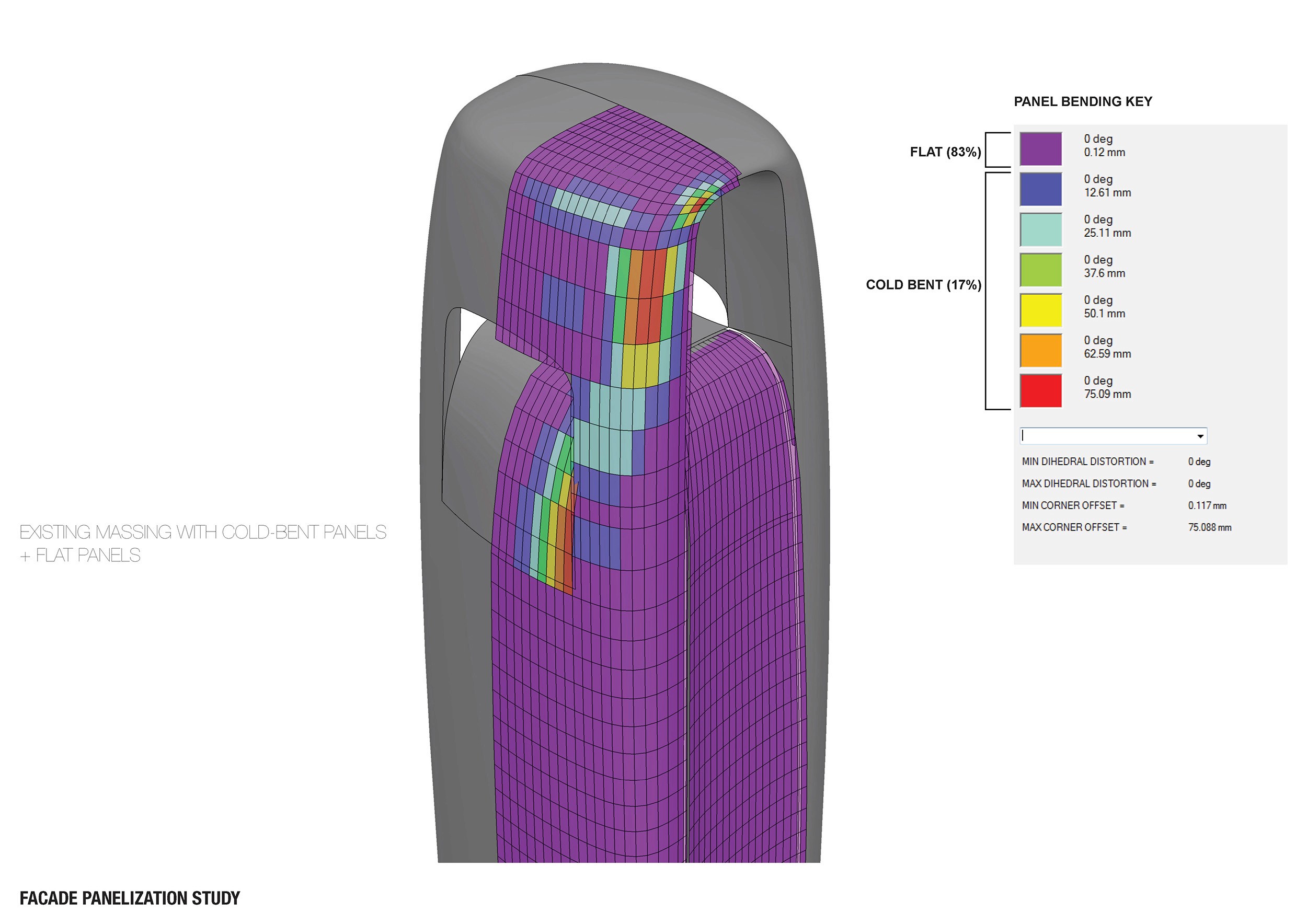

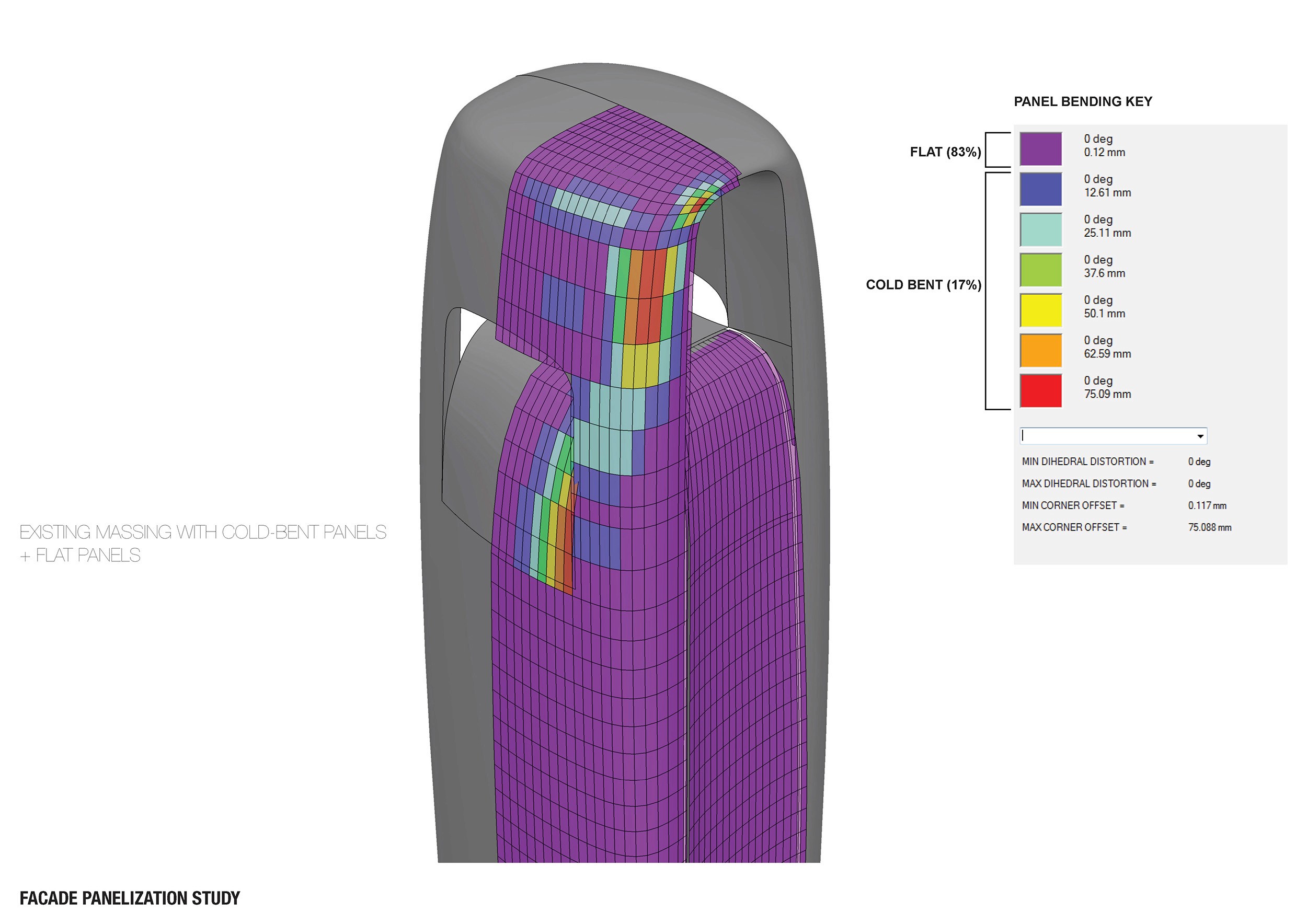

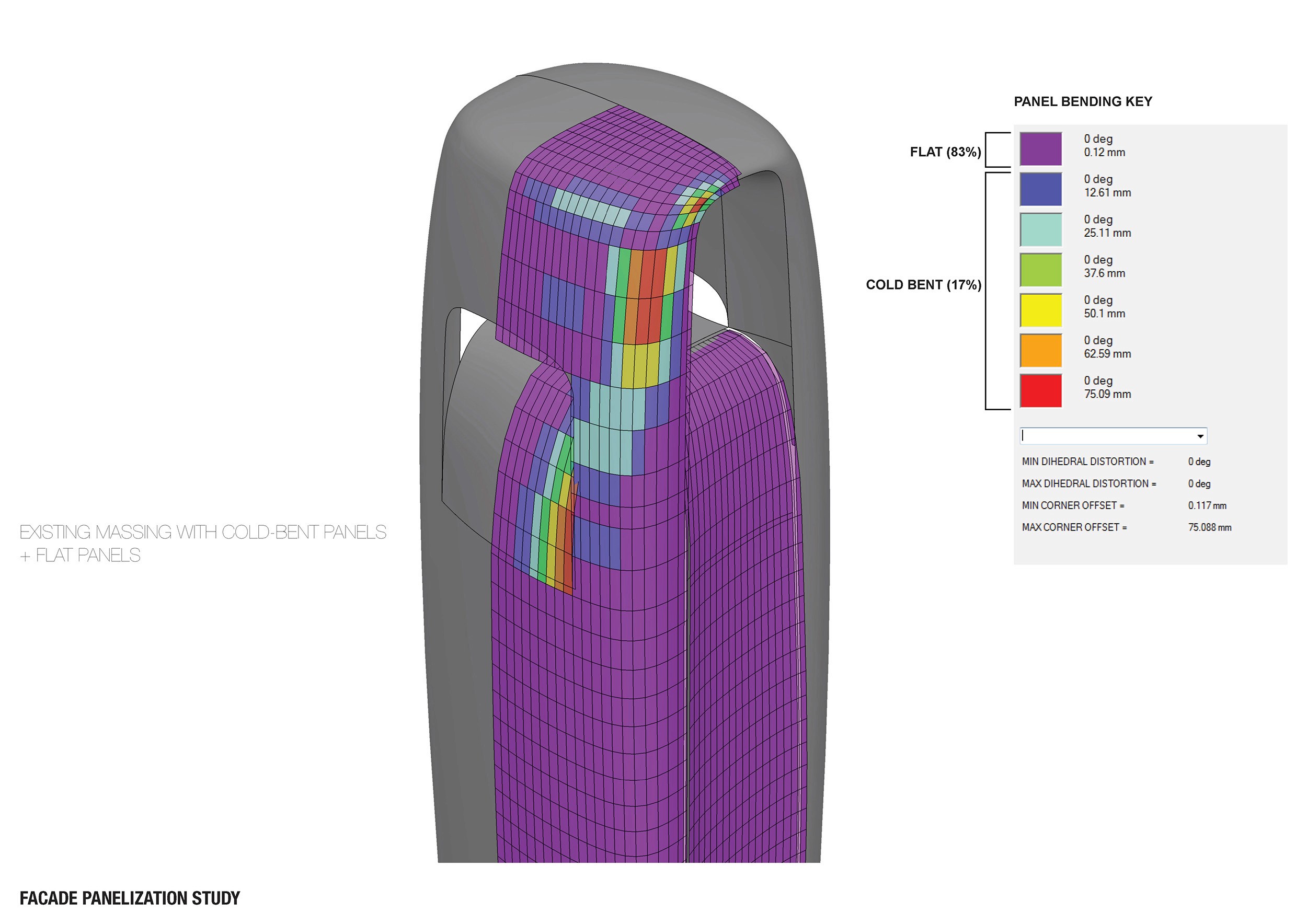

Due to the complex geometry of the building massing, Exterior wall panelization was optimized for the curtain wall manufacturer in order to maximize the number of flat panels and reduce the amount of panels requiring cold bending.

Due to the complex geometry of the building massing, Exterior wall panelization was optimized for the curtain wall manufacturer in order to maximize the number of flat panels and reduce the amount of panels requiring cold bending.

Due to the complex geometry of the building massing, Exterior wall panelization was optimized for the curtain wall manufacturer in order to maximize the number of flat panels and reduce the amount of panels requiring cold bending.

a similar exercise was required for exterior shading devices to achieve the tapered effect along the two primary facades of each tower.

a similar exercise was required for exterior shading devices to achieve the tapered effect along the two primary facades of each tower.

a similar exercise was required for exterior shading devices to achieve the tapered effect along the two primary facades of each tower.

05

CONSTRUCT

Building

Building

Building

Perforated metal was selected by ML/W for the shading device to reduce material weight and wind uplift.

Perforated metal was selected by ML/W for the shading device to reduce material weight and wind uplift.

Perforated metal was selected by ML/W for the shading device to reduce material weight and wind uplift.

curtain wall panels & Shading devices were shipped flat and assembled on site prior to install.

curtain wall panels & Shading devices were shipped flat and assembled on site prior to install.

curtain wall panels & Shading devices were shipped flat and assembled on site prior to install.